Vern Puchalski, on January 22, 2019, 11:00 AM

Understanding Dispatching Timers

Both Maximum (must do before…) and Minimum (block until…) Timers controlling allowable time between two separate operations are commonly found in manufacturing. Although critically important, they are almost never elegantly implemented for the operator and are a constant source of confusion and wasted effort.

After months of process investigation, you find that yield or other considerations clearly track to the elapsed time between processing at certain operations. You either need to block processing to allow a lot rest time or need to speed processing between two points for oxidation, cleanliness or related reasons. Now what? No one seems to agree where and how timers should be implemented in factory systems. Operators may or may not have visibility of timers. Worse, defining a Maximum Timer is actually delaying lots from processing due to confusion and lack of visibility. Living at the factory and watching every lot selection appears to be your only recourse. Is there a better way?

Understanding Timers

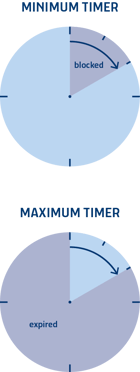

Before we go too far, let’s be sure what we’re talking about. Min Timers – block an operation until specified elapsed time, Max Timers – limit the maximum amount of elapsed time allowed between two time-critical operations. Timers are typically set at the track-out of one operation and enforced (Min Timer) or cleared (Max Timer) at another operation one or more process steps later.

The Min Timer is designed to prevent a subsequent step until a sufficient amount of time has elapsed. This may be created to allow cooling, epoxy set, etc. The operator may not select and run the lot at the blocking operation until a pre-determined amount of time has elapsed at that specific Process Step.

The Max Timer is designed to ensure that Process Z must be started within a certain time after the end of Process Y. If the timer expires, put the lot on hold to prevent the lot from running and initiate the standard disposition process by a Process Engineer.

Operator Visibility

The key to making all this work is easy visibility to the operator. Accurate timer condition must be visible in the dispatch List.

In the case of a Min Timer, lots should simply be “greyed-out” and not selectable until the instant that the Min Timer expires when the lot automatically becomes runnable. The operator should not have to take any action to refresh the list or guess at the timer state of any lot.

In the case of a Max Timer, the lot should be selectable right up until the exact time the Max Timer expires. At expiration, the lot must immediately be clearly marked as expired and no longer be available for selection by the operator. In no case do you want the operator to waste even one second considering a lot that has expired.

Max Timer Promotion Considerations

The whole purpose of a Max Timer is to get the lot processed before the timer expires. To accomplish this goal, it’s critical that both an expiration time and a warning time be defined. In all cases, lots should automatically be promoted on all dispatch lists immediately at warning time. This should put the lot high on the list and encourage the operator to select and run the lot, thereby preventing the timer from expiring. Some factories promote all lots immediately after setting a Max Timer to encourage fast cycle time through the timer loop.

Expired Max Timers

In the unfortunate (hopefully very rare!) case where the Max Timer actually expires, you must induce consequences and assign a responsible party. If you don’t assign a responsible party and consequences, then you risk a profusion of unnecessary timers in the factory that no one enforces. The accepted way to acknowledge a non-optimal condition and assign a responsible party is to put the lot on hold with a specific code (ex “TIMEREXP”). This will document the expired timer, inform Process Engineering of the issue and provide a mechanism to disposition and resolve any issue with the expired timer. It’s key to disable the timer once expired so that the lot does not continuously reflect “TIMEREXP”.

Final word

If your factory has a real need of timers, ensure that they implemented in an operator-friendly manner. Make sure the timer is visible in the standard lot selection process, help the operator succeed in satisfying the timer requirement and put real teeth (auto lot on hold) into Max Timer expiration.

January 22, 2019, 08:45 PM

Jens Kutschke

Great article, thanks for sharing. I find it increasingly difficult to manage timers as their number grows or when running a highly loaded fab. It might even be required to delay material from entering operation A, e.g. when there is a max timer from A to B and B is currently facing an exceptional situation such as unscheduled equipment down. Dispatching is limited by its "local" optimization nature, and larger number of timers can be a driver for looking into scheduling. Also, from a process perspective, frequent reviews of existing timers can be a good idea. Many times, yield issues requiring timers can be solved by means of process changes, and the timer can be avoided. Timers increase complexity - therefore (1) avoid whenever possible (2) tackle with dispatching if there are few timers or use cases are rather simple and (3) look into scheduling when hitting limitations with (2). Regards, Jens

January 24, 2019, 01:40 PM

Erin Peacock

Great points! Thanks for the feedback, Jens.