Dr. Holger Brandl, on May 10, 2023, 01:31 PM

Optimizing Semiconductor Production with Scheduling, Dispatching, Digital Twin & AI

To support rapid growth and increasing demand, semiconductor manufacturers are turning to advanced technologies such as scheduling, dispatching, digital twin, and machine learning methodologies. By combining these approaches, semiconductor manufacturers can create an efficient, automated manufacturing system that delivers significant benefits.

The Importance of Scheduling and Dispatching for Manufacturing Processes

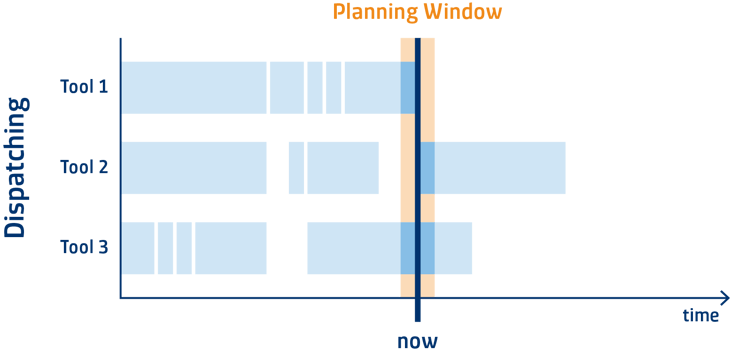

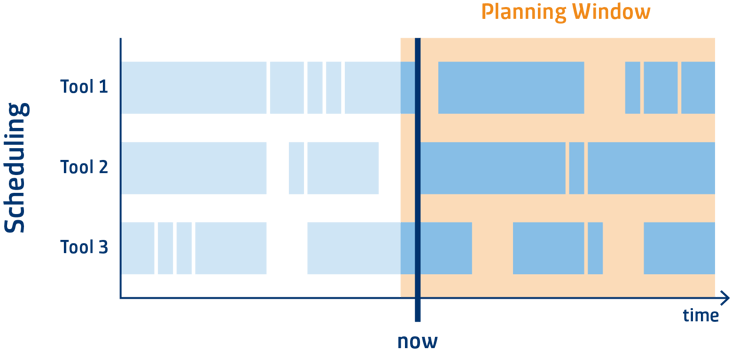

Scheduling and dispatching are complementary concepts in manufacturing processes, but they are distinct activities that serve different purposes.

Recognizing the subtle nuances between scheduling and dispatching is crucial. Dispatching systems respond to production floor events in real-time by analyzing resources and events to optimize production flow.

On the other hand, scheduling involves arranging, controlling, and optimizing workloads and work processes in a manufacturing or production process. Unlike dispatching, a scheduler devises an optimal plan before execution, allowing for a more efficient allocation of resources such as machinery and personnel. The goal of scheduling is to minimize production costs and time by determining when, what, and how to produce using the available equipment and staff.

Scheduling and dispatching are crucial components of any manufacturing process. These methodologies allow manufacturers to optimize their production schedules, ensuring that each machine is being used to its fullest potential. By using scheduling and dispatching software, manufacturers can reduce downtime and increase productivity, resulting in higher yields and lower costs.

Understanding Digital Twin Technology and its Applications in Semiconductor Manufacturing

Digital twin technology takes scheduling and dispatching a step further by creating a virtual replica of the manufacturing process. A digital twin can be used to simulate the entire manufacturing process, from the raw materials to the finished product. This allows manufacturers a risk-free way to test different scheduler configurations and optimize their production process before implementing changes in the real world.

Utilizing Machine Learning Algorithms to Analyze Manufacturing Data

Machine learning algorithms can be used to analyze the data generated by scheduling, dispatching, and digital twin technologies. By analyzing this data, machine learning algorithms can identify patterns and make predictions about future production outcomes. This information can be used to optimize production processes, reduce waste, and increase yield.

Benefits of Combining Advanced Technologies in Semiconductor Manufacturing

- Higher yields and lower costs with automated manufacturing processes

- Optimized production processes with digital twin technology

- Reduced waste and increased efficiency with machine learning algorithms

The benefits of combining scheduling, dispatching, and digital twin technologies are numerous. First and foremost, automated manufacturing processes result in higher yields and lower costs. By using scheduling and dispatching, manufacturers can ensure that their machines are always running at peak efficiency, minimizing downtime and increasing productivity.

Digital twins allow manufacturers to test different scenarios and optimize their production processes, resulting in even higher yields and lower costs. By simulating the manufacturing process in a virtual environment, manufacturers can predict and eliminate bottlenecks and optimize their workflows.

Finally, machine learning algorithms can be used to analyze shopfloor data to reveal patterns, trends, and anomalies. This helps production staff unravel the potential for line control improvements. By identifying patterns and making predictions about future production outcomes, machine learning algorithms can help manufacturers optimize their processes and reduce waste.

The Role of Advanced Technologies in Semiconductor Manufacturing

Ultimately, the combination of scheduling, dispatching, digital twin, and machine learning methodologies offers significant benefits to semiconductor manufacturers. By automating their manufacturing processes, companies can achieve higher yields, lower costs, and greater efficiency. As the semiconductor industry continues to evolve, it’s clear that these advanced technologies will play an increasingly important role in ensuring success.

Be the first to comment.