Significant advances have been made in the areas of manufacturing IT and automation solutions over the years. However, production managers still don’t always have information about all of the machines on the shop floor to fully optimize the operational performance of their manufacturing sites. The missing pieces usually involve the current and historical states of equipment and machines which leads to inability to:

- Accurately assess the current state and utilization of equipment

- Identify which machines are bottleneck

- Determine which machines are not running at their full potential

- Recognize which equipment has problems and down time in general

- Easily spot equipment that is wasting energy and resources

- Pinpoint which machines are experiencing idle time as a result of missing workers/operators

- Identify and locate carriers and material

Efficient maintenance planning and scheduling is also hindered by not exactly knowing the machine usage, conditions, and trends which are indicative that maintenance is required. Furthermore, to fully leverage applications such as predictive maintenance and AI-driven dispatching/scheduling, it is necessary to know the current and historical states of all equipment and machinery on the shop floor.

What is the Industrial Internet of Things (IIoT)?

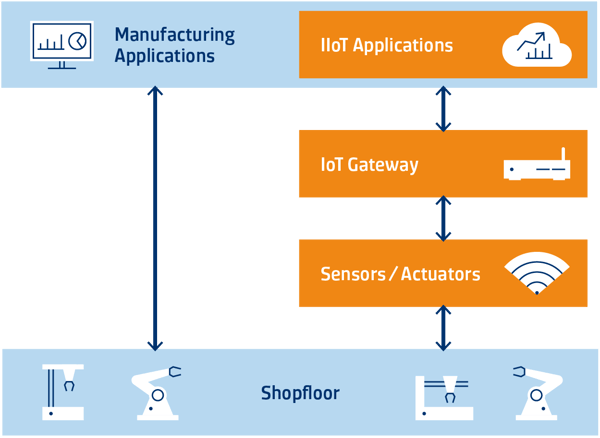

Industrial Internet of Things (IIoT) is the key to gather additional data from your shopfloor and gain crucial insights for optimization. This typically involves adding sensors to your machines to measure physical parameters, such as vibration, temperature or power consumption, or to capture more advanced data with barcode readers or cameras. Additionally, actuators like displays or relays can feed back information to the machine.

All of these devices transmit data (often via a small industrial PC or edge gateway) using standard internet communication protocols (TCP/IP). Edge gateways frequently handle protocol translation, buffering, and compression before publishing enriched data streams into message-oriented middleware (MOM), ensuring data arrives contextualized and usable by higher-level systems.

The result is that IIoT doesn’t just digitize the machine state (“running,” “down,” “material arrived”), it creates a more data-rich environment that combines tool data with environmental, vibration, acoustic, and energy signals. This augmented dataset can then be processed locally at the edge for speed and resilience, or streamed to IT applications for deeper analysis.

IIoT Connectivity & Data

Ideally, equipment vendors offer an option to integrate and even remotely control shopfloor equipment via a communication interface. For example, SECS is standard in the semiconductor industry, manufacturing equipment often has an MTConnect interface, and OPC UA and Web Services are more generic examples. However, such options may not be available sometimes or come with prohibitive costs. If the equipment doesn’t provide an adequate communication interface and, therefore, is not integrated within the manufacturing IT landscape, current and historical equipment data is lacking.

IIoT offers cost-effective options to upgrade such equipment and build their digital twins — virtual models representing both physical and functional features. Instrumenting tools with IIoT sensors and connecting them via gateways bridges the gap between equipment and IT systems, providing connectivity that would otherwise not be possible.

Imagine, for example, a standalone machine with internal automation but no communication interface to the outside world. If the operator pushes the start button, the machine would start to process all units that are available at the input port. However, there is no way of automatically tracking the machine status to enable a higher level of automation or optimization. An IIoT solution can close that gap.

For example, the green “running” signal light of the machine could be connected to an IoT Gateway’s digital input to measure and report the machine’s productive time. An additional presence sensor at the material input could trigger a warning if material is missing, or enable counting the number of produced units. The gathered data would then be processed by the IoT gateway, ingested into the digital twin model within the IIoT application and made available via an interface meeting the factory IT requirements (e.g. web services, MQTT, Apache Kafka, Azure IoT Hub, TIBCO/RV, or others). Via this interface, an OEE application can easily consume the data to generate statistics and throughput KPIs.

Use Cases

- Complementing an existing equipment interface with IIoT: If, for example, an interface doesn’t provide information about the machine’s power consumption. IIoT power sensors may be installed to provide more transparency of the machine's current status. With this additional data, the digital twin of the machine could be enriched to better understand the current equipment status and to enable further optimization.

- Facilitating the transition to “Place-and-Go” processing: Adding sensors and components (for example RFID readers for automatic material identification) to equipment that is already integrated facilitates the transition from manual material identification by the worker to a highly automated place-and-go scenario. Place-and-go capabilities then lay the foundation to enable automated material handling to be done by transport systems, autonomous vehicles and robots.

- Edge processing: Gateways provide low-latency filtering, schema validation, and anomaly detection before data enters enterprise systems.

- Improved predictive models: When IIoT data is fused with MES/equipment context, model accuracy rises materially, enabling earlier and more reliable detection of failures and bottlenecks.

IIoT Benefits

To realize the full value of IIoT, integration with higher-level applications (MES, ERP, Preventive Maintenance systems, etc.) is essential. Connected together, these enable manufacturers to reduce human error, optimize production, improve data collection and contextualization, and so much more.

Benefits

Replace error-prone manual processes with automation, such as automatic data collection in the MES

Identify idle machines and their true causes (e.g., no job, no operator, material missing )

Inhibit processing at a machine if other manufacturing applications do not allow this operation

Enrich manufacturing data with additional context information (e.g., program ID, recipe, chamber-level parameters)

Enable predictive maintenance with sensor-enhanced models

Enable “place-and-go” capabilities

To enable such applications, IIoT data is typically enriched with manufacturing data from multiple data sources relating to human, machine, material and method (4M). For example, it is common for existing machine interfaces to provide start and stop events indicating productive cycles. This data can be enriched using IIoT to provide deeper insights into processes. For example, one could provide temperature or vibration trajectories while an equipment is in production. This enhanced level of field data integration allows for factory analytics solutions such as data-driven predictive maintenance, quality and tool optimization.

Although, IIoT concepts and technology have matured considerably over last years, it remains a challenging task to implement such solutions. In particular, the velocity, the volume, and variety of these data require scalable infrastructure and a cutting-edge computing paradigm. The key to success is an efficient approach to model stream event processing to ensure fault-tolerant, exactly-once semantics at millisecond precision.

IIoT Solutions

IoT solutions must provide the same availability and reliability level as the other factory assets and systems while also fulfilling functional, system, and cost requirements. As such, these solutions must embed into the existing factory automation and management. Apart from that, the solution also has to take availability and reliability requirements and potential performance restrictions of the existing IT infrastructure into account. Only if these requirements are met, IoT applications become real Industry 4.0 solutions complementing the backbone of automated manufacturing sites. Simply stated, IIoT solutions are not “plug-and-play”, but have to be carefully architected and developed to ensure high ROI and stability.

Leveraging IIoT to the fullest extent is achievable but requires a high level of expertise, thoughtful implementation, and oversight. At a minimum, an IIoT deployment and management system is necessary in order to:

- Enable reliable software/firmware updates to IIoT devices with minimal effort required

- Provide visibility into IoT gateway connectivity status to verify everything is connected and running properly

- Ensure that a fleet of IIoT devices can be operated and managed smoothly

Getting Started

With the variety and maturity of components now available, the barriers to IIoT adoption are lower than ever. Whether the goal is to improve OEE, reduce energy waste, enable predictive maintenance, or feed AI-driven scheduling, IIoT closes gaps between machines and IT systems.

By combining tool-native data with IIoT sensors and edge processing, manufacturers gain not just visibility into “what happened,” but predictive insights into “what will happen next.” This sets the stage for iterative automation projects that scale toward adaptive, high-automation factories.

SYSTEMA’s Perspective

SYSTEMA has been providing software solutions and consulting on manufacturing automation for 30 years across many industries. We bring expertise in IIoT system design and integration, standards-based connectivity, and predictive-ready architectures. By bridging legacy equipment with edge-enabled IIoT and contextualized MES integration, SYSTEMA helps manufacturers unlock hidden capacity, anticipate failures earlier, and accelerate their digital transformation journey.