In the early days of manufacturing, paper lot travelers were structured for the manual collection and recording of all necessary processing data like lot number, product, process step instructions, equipment recipes, quality control data, etc. As manufactured products have become more sophisticated over the years, more advanced approaches to data collection have been developed.

Paperless Manufacturing

Paper travelers have largely been replaced by manufacturing execution systems (MES) for process controls and for the capture of product and processing data such as product, lot number, quality data, and timestamps for track-in and track-out operations. Dedicated statistical process control (SPC) systems have been developed to collect and process metrology data necessary for controlling product quality. Advanced process control (APC) systems make use of sensors and other devices to monitor the health of shop floor equipment and provide verifications, such as to verify temperatures within an oven chamber, which allow for process optimization and provide information necessary for determining necessary equipment maintenance.

Each component described above has unique needs and requirements in terms of data collection. Often the data associated with these systems is siloed, which contributes to inefficiencies related to data redundancy, accessibility, visibility, and scalability. To address these issues, data warehouses eliminate silos, provide timely access to accurate data, and provide a global, single-source of truth which allows engineers to efficiently analyze and evaluate conditions and methods that affect quality and, ultimately, revenue.

Warehousing and Leveraging Data

Advanced manufacturing processes invariably produces terabytes of production data and the quantity of data will only increase as products become more complex. More data doesn’t necessarily mean more information though. Comprehensive production control systems capable of reporting and visualization of factory performance in real-time are still a vision for most existing factories. The data exists but the ability to derive meaning is hindered by challenges related to aggregating data once information becomes siloed within individual systems.

On one hand, individual IT systems provide critical manufacturing performance information within their specific domain, but efficiently gathering and making use of information across multiple domains is no simple task. Careful data collection methodologies and tools can solve this problem and enable the following:

Root cause analysis – single source of truth for manufacturing data becomes crucial for the quick identification of trends and patterns to determine the true root cause of quality issues. Analysis of collected data can significantly accelerate root cause analysis efforts.

Real-time reporting – deriving meaning from real-time production data enables visibility into live reports on metrics such as throughput, WIP, cycle time, flow factor, equipment utilization, yield, quality and on-time product delivery.

Traceability – automating data collection regarding dates, times, equipment, batches, lots, workstations, equipment operators and production methods enables traceability and provides the ability to identify, isolate, and rectify quality issues before products leave the factory.

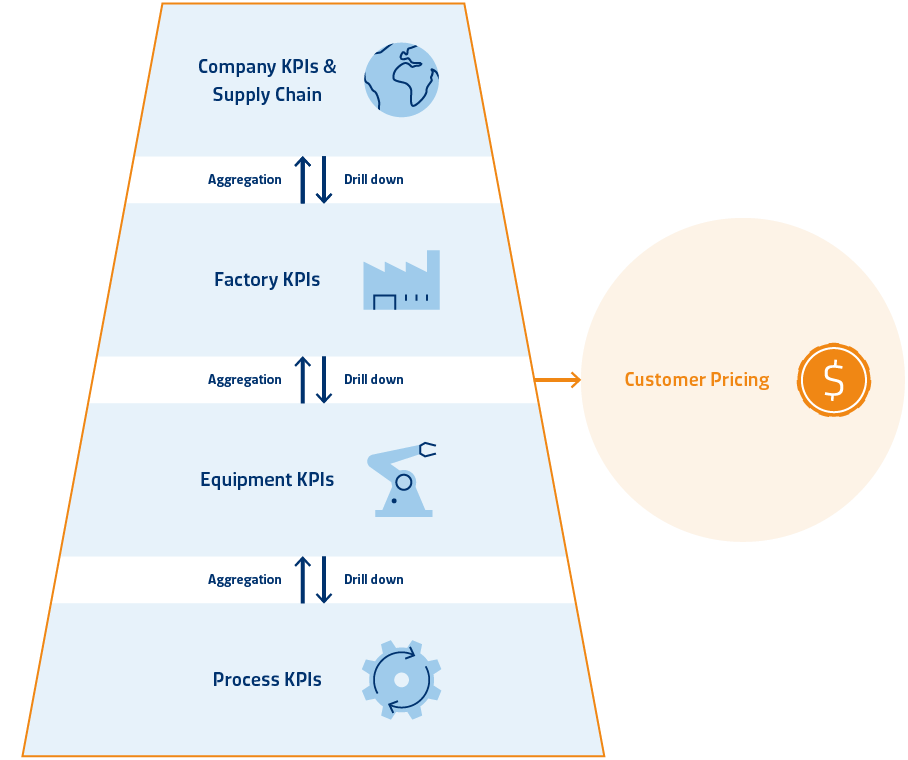

Product pricing – with the collected data from the point of product order up to product fulfillment, it becomes possible to associate individual processes with a manufacturing cost in order to accurately price products and optimize margins.

Break-even points for capital expenditures – calculate and capture break-even points for equipment investments.

Increasingly, this same consolidated and contextualized data is also what fuels predictive AI. By feeding high-resolution production data into machine learning models, manufacturers can forecast cycle times, predict bottlenecks before they occur, optimize scheduling decisions, and even simulate the impact of proposed process changes before they are implemented on the shop floor.

Benefits

Root cause analysis

Real-time reporting

Traceability

Product pricing

Break-even points for capital expenditures

Collecting Production Data

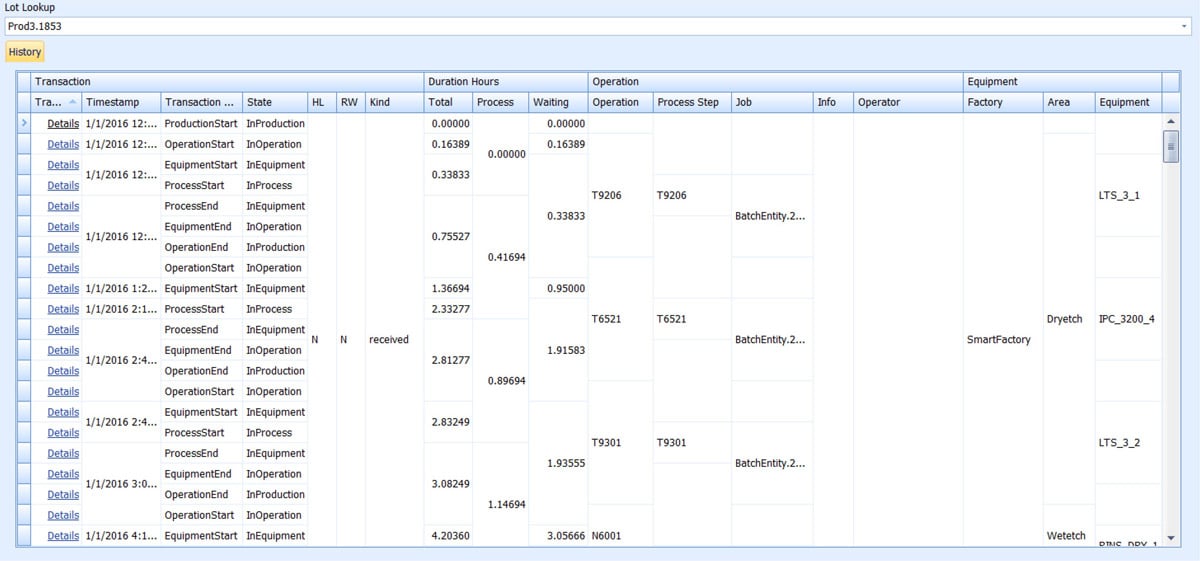

As equipment, lot and related data is generated with each production process, it becomes possible to generate real-time operational reports and, simultaneously, collect and record the raw data as a genealogical record and for the purposes of analyzing historical transaction data within other, more advanced, reports. The types of digital records, shown below, effectively render the paper traveler obsolete.

Lot Genealogy Data

The lot transaction history displays a tabular and granular view of a lot’s journey through operations, showing duration, process parameters, and equipment used. In addition to providing a detailed audit trail, this historical data can be used to train machine learning models that forecast cycle times, predict bottlenecks, and recommend routing adjustments. By analyzing rework loops, delays, and flow variations, models can simulate “what-if” scenarios and support more effective production planning, ultimately reducing variability and improving throughput.

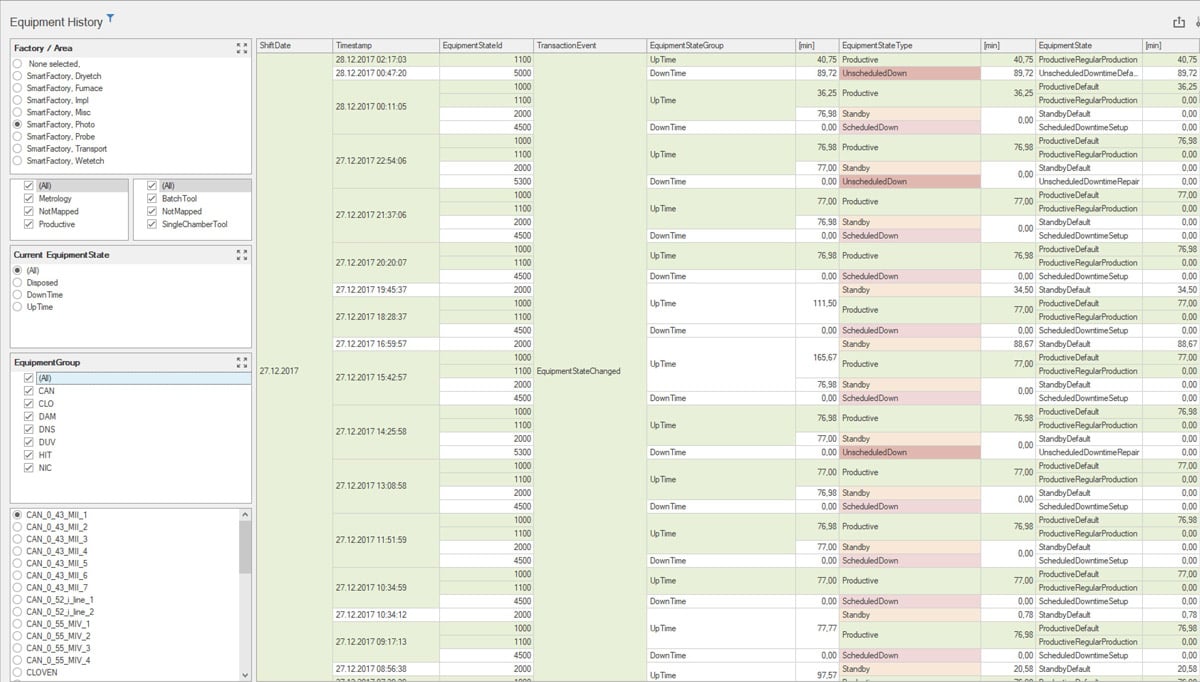

Equipment History Data

Historical equipment data enables detailed reports on equipment utilization, OEE, and many other customizable reports. Beyond reporting, this historical record provides the training data required for machine learning models. By analyzing past equipment behavior, process conditions, and performance outcomes, these models can identify patterns that predict future events—such as when a tool is likely to require maintenance, or how process conditions affect yield and cycle time. In this way, equipment history data supports not only retrospective analysis but also predictive maintenance, anomaly detection, and process optimization, allowing manufacturers to minimize unplanned downtime, extend tool life, and continuously improve production performance.

Once the data is collected and accessible, the types of reports which can be generated are only limited by the user’s imagination.

Below are examples of some common reports:

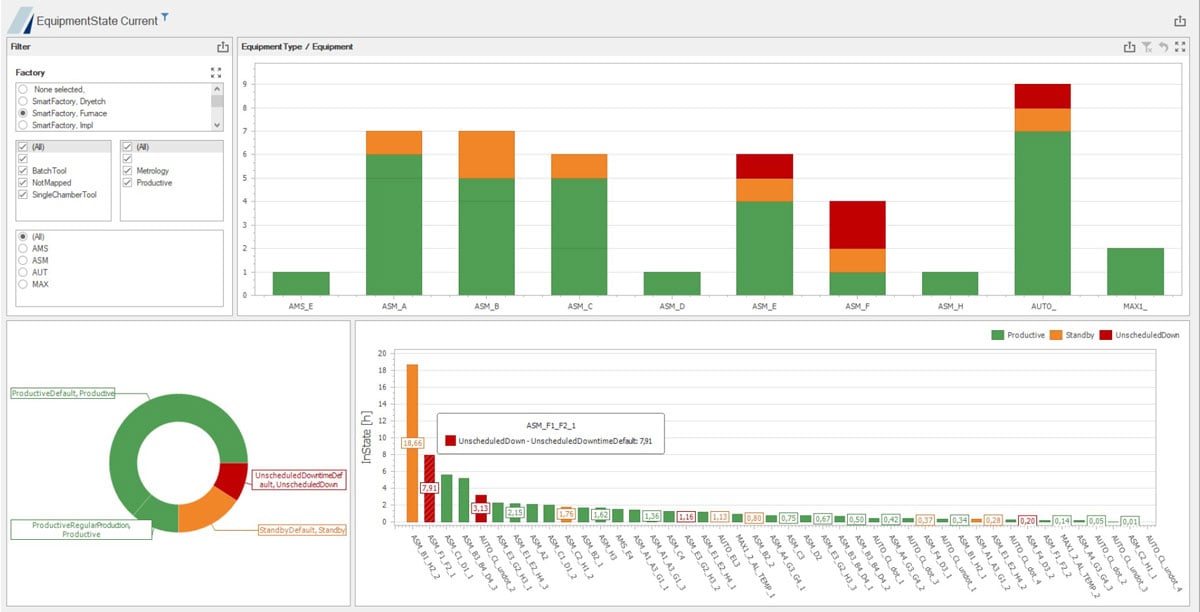

Equipment State Reporting

This report provides insights on equipment utilization by showing the amount of time spent in productive, engineering, standby, scheduled downtime, unscheduled downtime, and not scheduled states.

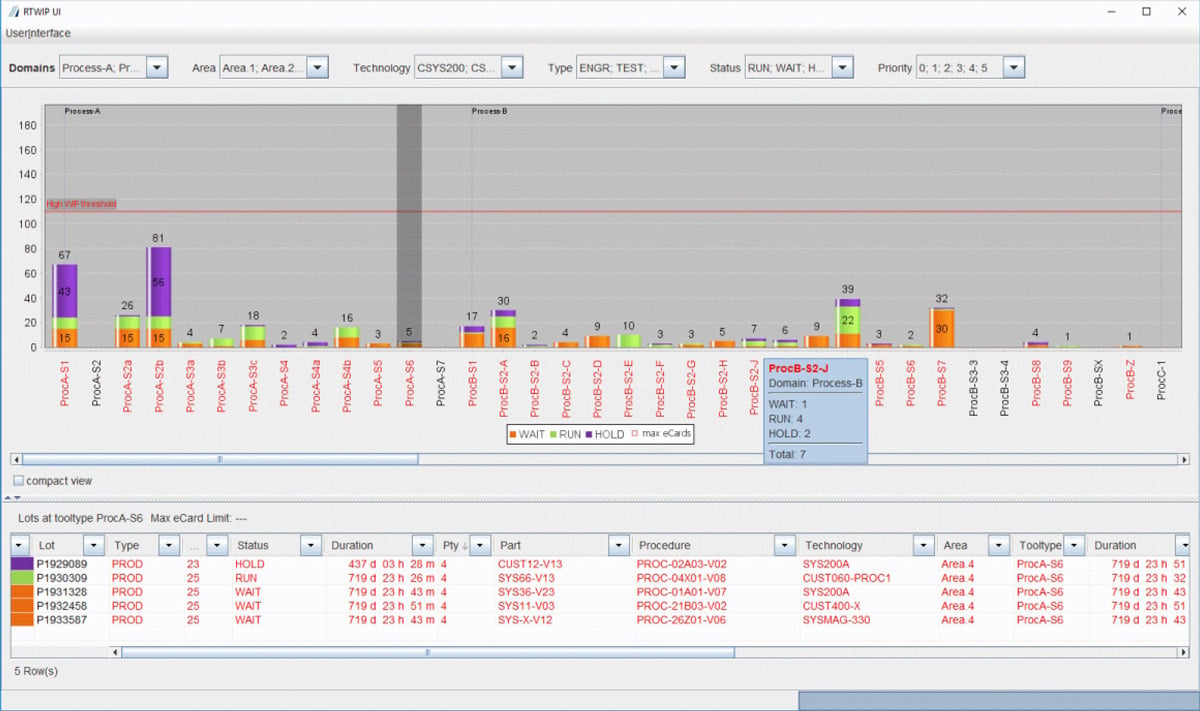

Real-Time WIP Reporting

Real-time WIP reports allow for the visualization of WIP as it moves through the factory. The bar chart displayed below is configured to show the amount and status of WIP in real-time at individual process steps. Graphical elements of the bar chart can be selected to view detailed information about lots at a process step in the lot detail area.

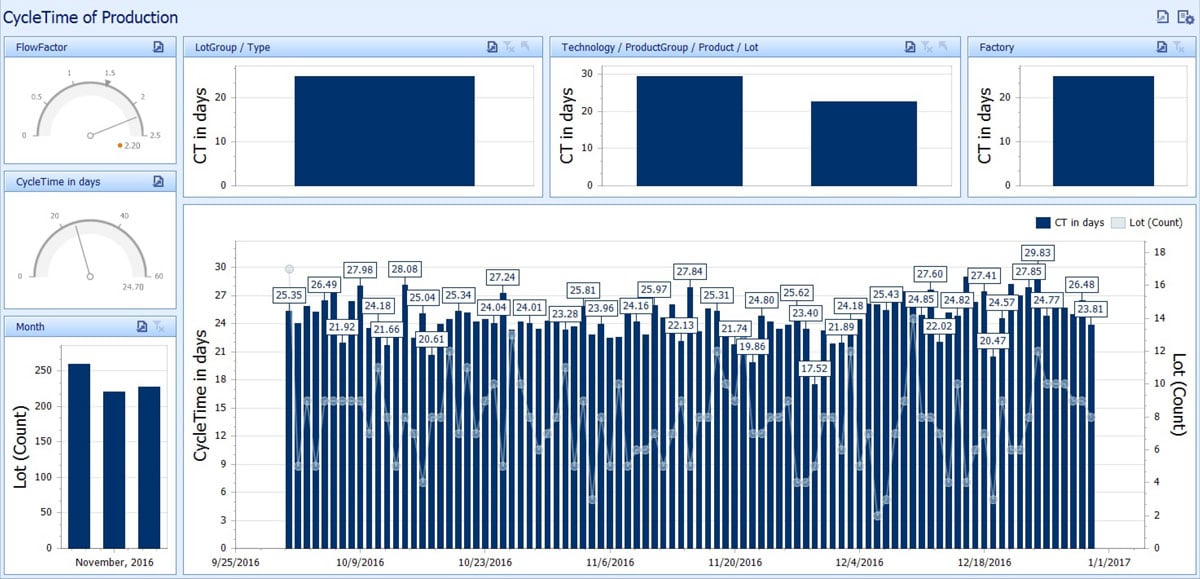

Cycle Time Reporting

Key performance indicator (KPI) dashboards, like the one below, display specific, measurable and quantifiable data critical to monitoring and optimizing factory performance. A cycle time dashboard indicates the time it takes to create a production unit from the time the production order is executed until the order is complete.

Approaching Automated Data Collection

Manufacturers typically know which areas on the production floor offer the greatest opportunities for improvement. Well-defined objectives will help to identify potential data sources so the work toward data collection can begin. This may mean that shop floor equipment requires upgrade or retrofit work in order to enable data collection -- thanks to the Industrial Internet of Things (IIoT), most legacy equipment can now be integrated with manufacturing IT systems without impacting tool functionality or stability. From paper travelers to the Industrial Internet of Things, all data can be digitally transformed.

SYSTEMA’s Perspective

For more than 30 years, SYSTEMA has helped manufacturers transform data collection from paper-based records into fully integrated, automated systems. Our experience shows that effective data collection is foundational to digital transformation: it enables real-time visibility of operations while also providing the historical depth required for predictive AI. With contextualized production data, manufacturers can forecast cycle times, anticipate bottlenecks, and implement predictive maintenance strategies. The same data also supports advanced planning and scheduling, allowing production plans to adapt dynamically to real-time shop floor conditions. By treating data collection as both an operational necessity and a strategic capability, SYSTEMA helps manufacturers move beyond monitoring the present to actively shaping future performance.