Advanced manufacturing requires careful coordination of resources, quality management, shop floor tools, equipment and human schedules, and quick responses to interruptions or unplanned events. Enterprise Resource Planning (ERP) systems manage company-wide resources, scheduling, and supply chain requirements. Most advanced manufacturers employ ERP systems to orchestrate high-level operations, but ERPs lack the granularity needed to put the right materials, in front of the right tools, at the right time on a dynamic and complex production line.

To fill this gap, an additional layer is required—responsible not only for executing manufacturing but also for collecting, storing, and contextualizing data about the process, enforcing repeatable requirements, and ensuring compliance and traceability. This layer is the Manufacturing Execution System (MES).

What is an MES?

The Manufacturing Enterprise Solutions Association (MESA) defines an MES as the following:

“A Manufacturing Execution System (MES) is a dynamic information system that drives effective execution of manufacturing operations. Using current and accurate data, MES guides, triggers and reports on plant activities as events occur. The MES set of functions manages production operations from point of order release into manufacturing to point of product delivery into finished goods. MES provides mission critical information about production activities to others across the organization and supply chain via bi-directional communication.” 1

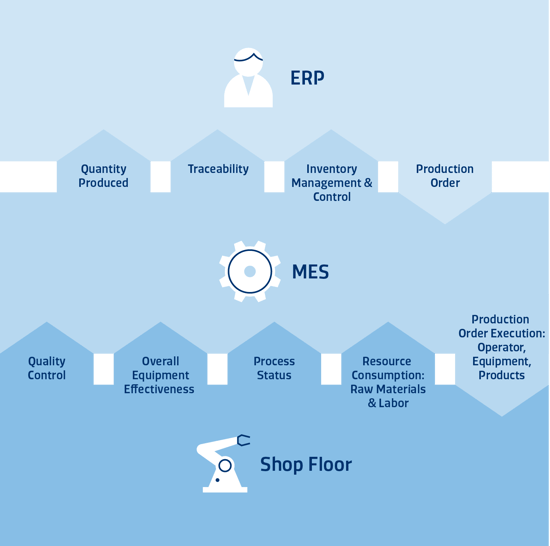

Put simply, the MES orchestrates production by synchronizing orders, materials, equipment states, operator actions, quality checks, and genealogy. It bridges planning with shop-floor realities, ensuring compliance, repeatability, and traceability.

Consider the everyday analogy of baking a cake: ingredients must be procured, supplies gathered, and due dates defined. ERP ensures all the pieces are available, but the execution system provides the recipe, ordered steps, cook times, and acceptable alternatives if substitutions or optimizations are needed. Similarly, the MES provides structure and orchestration to turn planning into reliable execution.

The MES at the Core

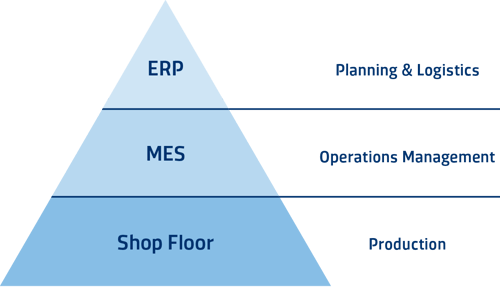

Architecturally, the MES sits between ERP systems and tool-level control systems. It enables the free flow of information in both directions: from ERP to MES to automation, and vice versa. ERP provides global orchestration; MES focuses on factory execution, managing processes, steps, flows, and equipment.

ERP, MES, and automation systems must work seamlessly together—one system’s output becoming another’s input—so that the manufacturing process is scalable, predictable, reliable, and visible.

MES solutions vary widely: home-grown vs. commercial, industry-specific vs. generic, on-premises vs. cloud, text-based vs. modern UIs. In some cases, ERP and MES are tightly integrated into a single application; in others, they remain distinct. Regardless of implementation, the MES provides core capabilities that support digital transformation.

MES Core Components

The MES can answer the following questions:

- How to produce?

- What can be produced?

- When and what should be produced?

- When and what was produced? 2

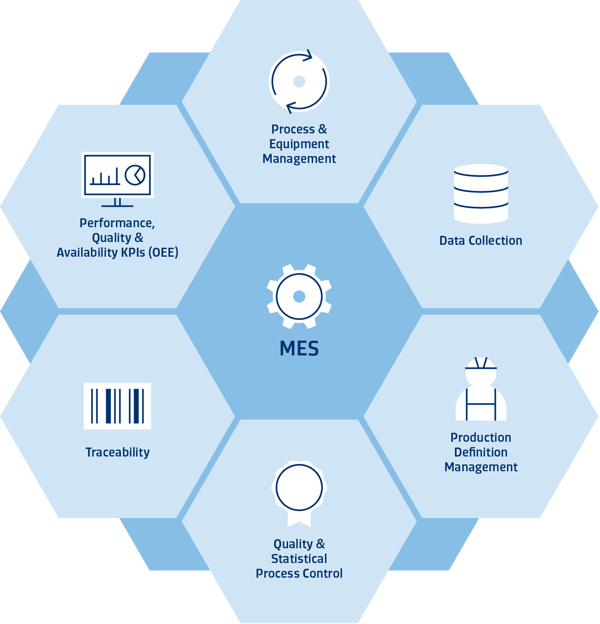

To answer these questions, MESs implement and manage the following core components:

- Enumerated steps – a step is an atomic value-added activity on work in progress that, when connected sequentially with other atomic steps in sequence, creates a finished sellable product. These steps are often enumerated numerically, although some MESs may permit alphanumeric conventions.

- Process flow control – the above-enumerated steps are placed in sequence resulting in a defined and reusable process flow. MESs excel at managing process flows regardless of whether they are just a few steps or whether they are multiple process flows chained together encompassing thousands of steps.

- Product definition – a product can be defined by a single process flow or a series of process flows chained together resulting in a finished product. Product definitions can also contain metadata which provides further granularity and classification of the product. MESs help to define products in both high- and low-product-mix environments. Versioning and product options are both visible to the end customer and transparent to the floor operators as process changes are programatically “activated” using metadata in the product definition.

- Equipment assignment – a process step is often attached to a tool or tool type. Therefore, when the material reaches a given process step, the MES knows what equipment is required for that process step. Some tools in a tool group may be better equipped to process a specific product. MESs may also be able to track a product to a tool that is running in a way that satisfies or optimizes the product’s requirements, thereby increasing quality and customer satisfaction.

- Real-time control – sometimes work in progress needs to be paused or stopped in the course of processing in order to further investigate or collect data. MESs allow for these pauses in support of any ancillary activity, including R&D of new products as well as optimizations of current products. These pauses can be real-time (at the current step) or future pauses at upcoming steps in the process flow.

- State logging – similar to flow control on work in progress, state logging identifies the availability of equipment to process work that arrives at the equipment station.

- Genealogy – each step completed in the process produces the next sentence in the story of the material being processed. Even after the material is shipped, its genealogy is available for review and further study in pursuit of process improvements or other uses.

- Regulatory Compliance – the components above serve as data points to support regulatory compliance requirements. Whether you are producing appliances, medications, microprocessors, vehicles, or component widgets, every industry has some level of compliance and certification required to produce parts for that industry. In many cases, component level tracking contributes to improved quality assurance statements and metrics, making an MES a necessity for a vast array of manufacturing certification.

AI Readiness

As factories evolve toward predictive and adaptive automation, MES plays a foundational role in preparing data and context for AI-driven applications:

- Emit high-granularity events (not just summaries) with stable IDs and consistent context fields

- Expose as-run recipes, parameters, and chamber traces to SPC, APC, and analytics systems

- Provide hooks for closed-loop actions, such as recipe adjustments or dispatch prioritization, enabling advanced control strategies

Outcomes

With an MES in place, manufacturers gain the ability to collect, control, and report real-time information. KPIs such as cycle time, critical ratio, SEMI-E10 equipment metrics, OEE, and other performance data become available within the MES or can be extracted for use in business intelligence platforms.

As the foundation of digital transformation, MES provides both immediate and long-term value. It orchestrates execution today, ensures compliance and traceability, and positions the factory for tomorrow’s intelligent planning and AI-driven optimization.

SYSTEMA's Perspective

For the past 30 years, SYSTEMA has been at the center of smart manufacturing—where MES has become a requirement rather than a vision. In that time, we’ve seen the boundaries between MES and ERP become increasingly blurred as both have expanded capabilities in an effort to serve as a single, monolithic solution. In practice, however, the most effective approach is not choosing one over the other, but customizing MES and ERP at the component level. This allows manufacturers to blend the strengths of both worlds into a complementary, coexisting application landscape—one that seamlessly plans, manages, and tracks manufacturing activities while preserving flexibility for future needs.

1 What is MES?: A & D Tech Eng. (n.d.). Retrieved December 2, 2019, from http://www.techeng.com.au/mes/what-is-mes

2 Siemens. (2008). Manufacturing Enterprise. Manufacturing Enterprise.