How can we make a manufacturing process more efficient? How can we produce more? How can we improve tool utilization? Can we do so without hiring new workers or buying more equipment?

A complex interplay of human, machine, material, and methods (4M) exists that drives a production process. At a certain level of complexity, this interplay won't always follow intuition. So, it is often very hard to answer these questions.

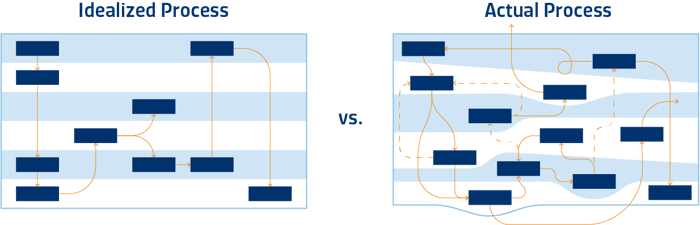

According to intuition, production processes often follow a clear structure. However, actual processes are usually more complex in nature including more inter-task dependencies that establish the checks and balances that keep production running smoothly. Simulation and modeling can help to disentangle this underlying structure into a formalized process description.

Furthermore, manufacturing processes typically grow over years to meet targets and requirements. If the business is thriving, these processes evolve with good intent from all participants but sometimes lack structured documentation. With different departments (engineering, operations, logistics) being involved, it becomes increasingly difficult to work out cause-effect relations when preparing process improvements.

To enable process engineers to improve and optimize complex production processes, a formalized description of a manufacturing process is required and serves to democratize and document the manufacturing process. We need to unravel the structure of the hidden factory – that is, processes that live inside an organization without any documentation or formal specification.

Benefits

Benefits

Gain insights needed to boost manufacturing performance

Optimize forecasting & capacity planning

Increase visibility of manufacturing processes

Risk-free process experimentation

Optimize throughput & productivity by resolving bottlenecks

Cost-efficient process optimizations through experimentation

What is a Simulation Model?

Simulation Modelling is the key tool of Business Process Management (BPM) which comprises various methods designed to discover, model, analyze, measure, improve, optimize, and automate business processes.

“Simulation is the process of designing a model of a real system and conducting experiments with this model for the purpose either of understanding the behavior of the system or of evaluating various strategies (within the limits imposed by a criterion or a set of criteria) for the operation of the system.“

Claude Shannon, 1975

A simulation model of a production process is one of the most powerful tools to boost operational efficiency, optimize resource usage, improve planning accuracy, and grow a business.

A simulation model allows the evolution of the real system and the study of its dynamics independent of the live environment. It allows for the exploration of alternate realities and process parameters including confidence bands. In contrast to the real system, the parameters and mechanics of a simulation can be altered arbitrarily to understand or optimize the underlying process.

Applications of Simulation & Modeling

Production modeling not only serves as a “living” documentation of processes, but also enables simulations that can result in a wide range of new tools, capabilities, insights, and improvements as depicted in the image below.

Optimize Forecasting & Capacity Planning

Capacity planning is crucial to determining necessary resources and throughput capabilities. Simulation is one of the best and most accurate means of achieving optimal forecasting and capacity planning.

When parameterizing a simulation model with the current state of a manufacturing process, we can use this model to make more accurate predictions. The model can be used to forecast future factory states. For instance, in logistics, simulation models provide more accurate estimates than Excel-based models because the latter typically lacks a detailed model of the process mechanics. In contrast, since a simulation model encodes a mechanistic model that can evolve state it is perfectly suited to predict a future factory state.

Simulation models are known to provide great accuracy for forecasting key manufacturing KPIs such as throughput or tool utilization. They tend to outperform statistical models because they encode the inherent mechanics of a production process.

Optimize Throughput & Productivity by Resolving Bottlenecks

Any model provides the opportunity to zoom into the aspects of a process that truly matter regarding its desired result and the actual outcome. That said, it is an abstraction of the real system with some risks of inaccuracy.

A simulation model is perfectly suited to validate hypotheses about possible bottlenecks or unused capacity in a manufacturing process and allows for the exploration of measures to improve the process. For instance, a bottleneck can dramatically impact the performance of a manufacturing process, increasing the cycle time or even causing a production stop. Simulation can reveal bottlenecks and ensure that by solving one bottleneck we avoid a cascading effect of bottlenecks at future process stations. Thus, simulation brings great potential for sustainable optimization.

Risk-Free Evaluation of Advanced Production Planning Methods

SYSTEMA recommends dispatching and scheduling solutions for optimizing factory planning and execution.

While dispatching and scheduling tools do provide tangible results, these types of tools aren’t designed to quantify the results of planned changes within the production environment. To ensure plans will deliver the intended process improvements, a simulation can be included to evaluate dispatching and scheduling outcomes before making any changes in the live production environment.

Simulations can be a powerful complement to existing production planning and control methods by adding insights and robustness. A simulation model of a manufacturing process allows the evaluation of process improvements quantitatively by simulating both current and future plans.

Cost-Efficient Process Optimizations through Experimentation

Sometimes, factory managers are unclear whether capacity problems can be solved by purchasing additional equipment or hiring additional staff because the dynamics of any sufficiently mature operation are usually very complex. It’s often impossible to understand an operation with just clever thinking. In contrast, with a simulation model in hand, it is possible to assess the impact of capacity changes, new (or fewer) resources, or more WIP before committing to a major purchase, recruiting effort, and process changes.

Before changing a process, it is financially advantageous to assess the impact of process changes in a simulated environment. This minimizes the risk that a process change introduces unintended side-effects from a non-trivial and unexpected interplay of production resources. A simulation model will also help to ensure a process change results in intended improvements.

Distinguishing between MES, Digital Twin & Simulation Technology

The interplay of various technologies on the factory floor can be complex and is frequently misunderstood. Common questions arising in terms of factory simulation and modeling include:

- Which manufacturing technology plays which role?

- How does a simulation model differ from an MES?

- Is a simulation model a digital twin?

The digital foundation of a factory is the manufacturing execution system (MES). The MES provides a basis for automation and drives effective execution of manufacturing operations. A simulation model needs to incorporate a basic digital representation of the MES as it exists today, but the simulation is not an MES. In contrast to a simulation model, the MES itself cannot effectively evaluate complex “what-if” scenarios without actually implementing changes in the live production environment at a high risk of adverse outcomes.

The simulation model abstracts some aspects of an MES that are relevant for a particular process and handles encoding processes typically not modeled in an MES, such as:

- Shift models

- Maintenance schedules

- Complementary activities of workers

A digital twin is defined as a digital representation of a physical asset. Very often, simulation models are parameterized from a digital twin solution (such as the RI Suite) before conducting risk-free evaluations and experiments.

In sum, the MES, digital twins, and models are independent tools used to provide simulation capabilities.

SYSTEMA's Role

To establish a simulation model of a manufacturing process, we guide manufacturers through the following aspects:

- Formalize the description of a process. This description needs to describe the mechanics and the decision processes that are happening – often in parallel – when operating a manufacturing process. It condenses and democratizes the operational knowledge of how production is executed.

- Define parameterization of the model. This typically includes several planning tools: the shift plan, orders, a product catalog, product routes, or any parameter that is relevant to operating a process.

- Select a technical framework. Basic processes can be studied in existing low-code simulation tools while more complex processes require the creation of custom models. The latter are built on top of simulation libraries that provide an engine to model resources, decisions, and interactions in discrete increments.

- Establish test and maintenance procedures for the model. Since a simulation is software-based, it needs rigorous checks to ensure dynamics and behavior reflect the actual system it represents. Some tests will be fully automated (so-called unit tests or CI/CD) and, to complement the testing efforts, analysts need to study a model to ensure its correctness. Since processes undergo constant refinement, a model also needs to evolve to match changing requirements.

When building a simulation, the level of abstraction is defined by the use-cases. In some situations, it may be sufficient to model areas in a factory as entities, whereas in other situations, we may need to model the individual activities of workers including their movements within a production area.