What is SYSTEMA RBA?

SYSTEMA’s Rule-Based Activities engine, RBA, is an application capable of allowing authorized production staff the flexibility to customize process rules according to specific requirements and streamline the processing of materials in the production line.

Rules-based processing is a method of automating decision-making and actions in a production process based on a set of predefined rules.

For example, in a manufacturing process, a rule might state that if the temperature of a particular machine exceeds a certain level, the machine should automatically shut down. In this case, the rule serves as a set of instructions that tell the system what to do when a specific condition is met.

The advantage of rules-based processing is that it allows for a more automated and efficient process, as well as increased consistency and accuracy. It also provides greater flexibility and control, as the rules can be easily updated or changed to reflect changes in the production process.

RBA allows production staff to create, modify, and enforce rules with relatively simple configurations and requires no complex programming. Seasoned production experts and newcomers will have the tools they need to manage production processes efficiently.

Benefits

Save time using an integrated real-time interface for all the data sources in your factory

Enable administrators, operators and management to gain deep insights into your factory processes

Increase transparency using an interactive shop floor interface

Solve problems efficiently with anomaly detection & event classification

Monitor factory health in real-time with automatic data aggregation & KPI dashboards

Understand log events with enriched context information

RBA Capabilities & Use Case Scenarios

RBA includes a range of advanced features, including real-time monitoring, automatic notifications, and a centralized database for storing and tracking all of your rules. This will help production staff stay informed about any changes to rules and ensure that the production line is always running smoothly.

Some potential production processes and use cases where RBA can be especially helpful:

Smart Sampling

Smart sampling can be used to determine under which conditions measurement steps may be omitted or optimized based on process quality data at the material level. When process quality requirements are met, fewer measurements are required. By measuring only what is necessary, cycle time decreases and less metrology equipment is required.

Timer Management

RBA can provide timer management capabilities when MES time handlers can’t provide the desired functionality or are absent entirely. Timers can be used to activate actions within other systems, such as: if a timer expires, send a message to the MES to place the lot on hold.

Quality Control

RBA can be used to complement communication between the MES and SPC systems to alert production staff to excursions, ensuring that production staff can manage the issues so that materials are processed according to specific standards.

Equipment Operational & Performance Qualification Alerts

By caching equipment performance data points, RBA can alert production staff if comparisons of current and previous data points indicate that equipment and systems are operating inconsistently or inaccurately, according to their intended purposes and predefined specifications.

Special Case Material Routing Support

RBA can be used to help manage complex or unusual routing cases that the standard MES doesn’t support.

Procurement Support

For the logistics of production, rules can be set to optimize the movement of materials and resources. Material requirement planning can be supported by enabling RBA to use information from production plans and bill of materials (BOM) to calculate the consumption of raw materials, components, and sub-assemblies. This helps assist with the timely procurement and movement of materials, reducing stockouts and production delays.

The provided examples of how RBA can be used in production processes are not exhaustive. Specific use cases will vary depending on the needs and requirements of the production staff.

How does it work?

RBA evaluates inputs against predefined rules and executes actions based on the results of the rule evaluation. This helps to automate decision-making and increase efficiency in the production process.

Rule Definition: The first step is to define the rules that will be used in the system by providing conditions/triggers and actions. This is usually done by production staff or a system administrator.

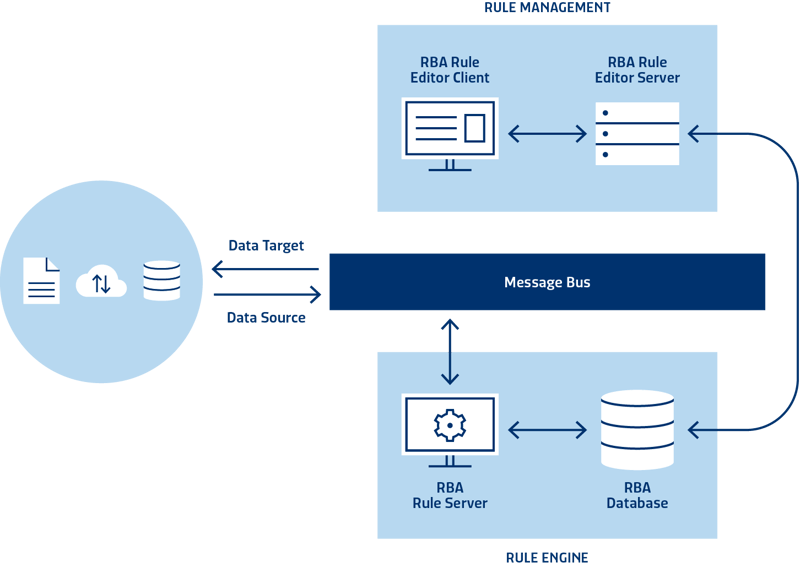

Input Processing: Using internal RBA timers and a message bus, the system takes inputs from various sources, such as sensors, manual inputs, or other systems, and evaluates them against the defined rules.

Rule Evaluation: Process inputs are evaluated in real-time, and RBA determines which rules are relevant to the current inputs to execute the appropriate action, if any.

Action Execution: Based on the results of the process conditions evaluation, the system executes the corresponding actions.

Rule Monitoring and Updating: The rules and the execution of the rules can be monitored and updated in real time, ensuring that the production process is always running efficiently.

RBA Components

RBA Rule Editor Client & Server

The RBA Rule Editor is a stand-alone client that is connected to the RBA Rule Editor server via a message bus. The editor facilitates rule setup activities and provides runtime views of rule definitions, histories, and triggers. User permissions include roles for reading, writing, and approving rules.

RBA Database & Rule Server

Responsible for executing rule logic at runtime.

Basic Functions Package

RBA is a rule engine application that allows customization and extension of basic functionality. RBA basic functionality includes:

- Flat or hierarchical rule set management

- Simple or combined comparison of two values which could be a fixed value or a value read from internal or external source. For instance, check message event parameters for specific values, such as event type, event owner, or facility, to determine appropriate action

- Basic sampling capabilities based on counters to track counts or time periods, preventive maintenance requirements, and timeouts and then take actions based on predefined rules

- Listening to equipment communication events in order to evaluate rules

- Responding to equipment communication to apply rules

- Exception management

Advanced Functions Package

The following extensions are available as add-ons to the basic functions:- Extended sampling capabilities to perform operations e. g. once a day and material, based on unique name patterns

- Data Store to enable stateful and multi-stage processing. This allows data storage in the RBA database to be available from execution to execution

- Expressions to enable syntax-driven functionality to perform numeric calculations or string operations for creating specific logic.

- Timers to enable self-triggered scenarios to automate actions within a defined interval. This package is used to automatically initiate, coordinate, and control various time-critical manufacturing operations or processes.

System Requirements

Client and Server host: Windows / Linux

Database: Standard market databases, customer-specific evaluations possible

Message Bus: Standard bus systems, customer-specific evaluation possible for component communication

Licensing

We provide a ready-to-use RBA application which is offered as a licensed software product, configured and run on-premise, with options for maintenance and support contracts based upon individual factory needs.

SYSTEMA provides training, and, if needed, services to integrate RBA with a manufacturing environment’s existing IT systems. After a short training, rules can already be implemented in the system independently.

To bring RBA to your shopfloor, we provide an iterative consulting process that involves:

- Technical workshops and demos to educate and introduce RBA and its capabilities

- Strategy and planning support to identify business objectives and priorities

- Consultations to clarify and validate business use cases and requirements

- Technical guidance and services for embedding RBA into the existing system architecture

- Support for the development of an RBA database schema

- Optional preliminary installation, without custom extensions, for user acceptance testing and training purposes

- Implementation of custom features, if any

- Delivery of RBA, including custom extensions, to a test environment for user acceptance testing and training purposes

- Rule set-up: For rule configuration, a standardized rule library is available for the respective module

- Demonstrator including MES simulation is available

- Deployment to the live production environment with a step-by-step ramp-up

Why SYSTEMA?

SYSTEMA has more than 30 years of experience in providing automation solutions and services to the manufacturing industry, particularly specializing in the semiconductor sector. We understand the challenges and risks involved in implementing automation on the shop floor and have a proven track record of providing training, consulting, and implementation services to manufacturers in various industries across the globe. Many of our solutions are customized to meet the specific needs of individual users, and all of our solutions come with the tools necessary to independently manage and leverage their capabilities.

SYSTEMA RBA is a customer-proven solution that has been operating for more than 20 years in 150 to 300mm semiconductor fabs worldwide.

For additional information on how to enable SYSTEMA RBA in your factory, please contact us.