- Jump to a section:

- Jump to a section:

Phase 1

MES with

Manual Interactions

- Operator driven workflow

- Minimal traceability

- No equipment integration

- Manual data collection

Phase 2

Basic Equipment

Integration

- One-directional connection: data from equipment to MES

- Automated data collection and cycle count

- Automated machine status

- Increased traceability, reduced failure rate

- Reduce opportunities for operator error

Phase 3

Equipment

Automation

- Single piece tracking; integrated scanner

- Bi-directional connection: data flow between equipment and MES

- Interlocking scenarios; increased process safety

- Paperless production

- Operators shift focus away from repetitive, low level tasks to higher level problem-solving

Phase 4

Integration of

Complete Lines

- Material transport and handling automation

- Line integration via process control unit (fully automated)

- Handling/loading steps using robots

- Higher throughput; higher quality

- Full traceability

- Opportunity for operators to expand production skills as maintenance tasks for robots, transport and automation will be needed

Phase 5

High Automation

- Fully automated production process

- Flexible transport units (AGV)

- Interlinked machines

- System driven workflow: operator in supervisory/oversight position

Phase 6

Lights Out Fab

- No operator intervention: fully automated failure and exception handling

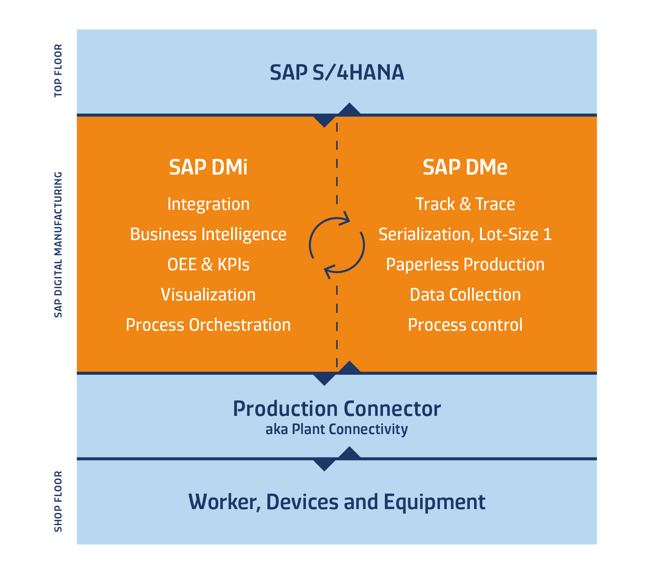

Digital Manufacturing with SAP Solutions

SAP Manufacturing solutions feature a modular structure that allows manufacturers to scale solutions tailored to their unique production needs. Whether managing basic MES functionality to control work-in-progress (WIP) processes, implementing paperless manufacturing with automated communication and decision-making, or advancing to highly automated systems requiring minimal human intervention, SAP Manufacturing provides the flexibility to meet your specific goals.

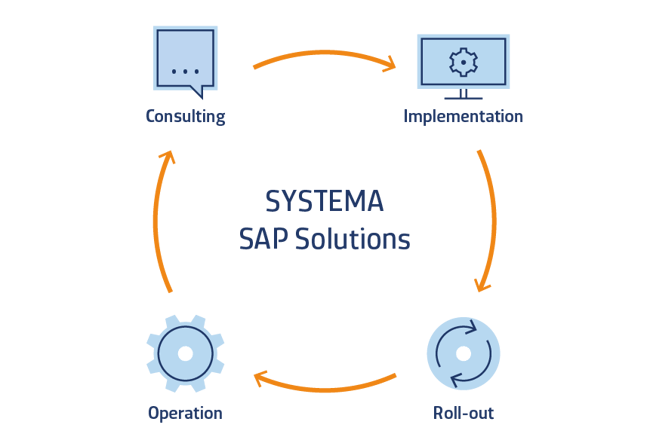

SYSTEMA supports these digital transformation initiatives with expert strategy, planning, and implementation services for key SAP Digital Manufacturing components.

To accelerate results, SYSTEMA offers MAX Suite, a powerful solution designed to enhance scalability, streamline operations, and reduce implementation time. By leveraging the SAP Manufacturing Solution and SYSTEMA’s expertise, manufacturers can optimize resource utilization, achieve operational excellence, and embrace digital transformation with confidence.

Explore the full portfolio of SAP Manufacturing solutions supported by SYSTEMA’s services below to discover how we can support your manufacturing transformation at every stage:

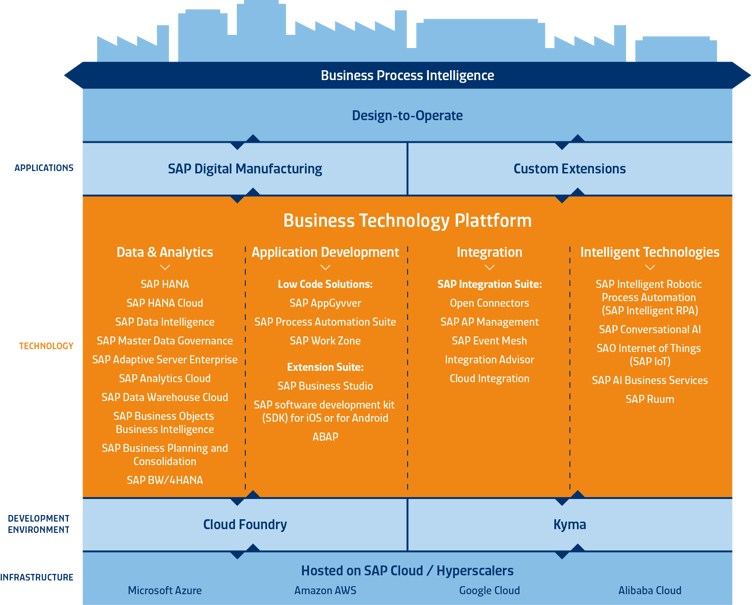

SAP Business Technology Platform

The SAP Business Technology Platform (SAP BTP) serves as the foundation for innovation and integration across SAP solutions, enabling enterprises to store, analyze, and act on vast amounts of data from internal and external sources, including partner organizations, customers, and sensors. The platform supports intelligent enterprise-building through its application development, integration, and intelligent technology pillars.

SAP Business Technology Platform (SAP BTP) is the foundation of the Intelligent Sustainable Enterprise that brings together data and analytics, artificial intelligence, application development, automation, and integration in one, unified environment.

Key Features of SAP BTP

SAP BTP offers a wide range of functions to support enterprise innovation and integration:

- Application Development & Automation: Provides a platform for cloud-native application development, enabling users to design and deploy custom workflows and robotic process automation (RPA) bots. It also supports extensions for on-premise systems and SAP SaaS solutions.

- Extended Planning & Analytics: Features an analytics frontend that facilitates integrated planning across various business functions.

- Data & Analytics: Offers solutions to store, ingest, combine, and govern data, as well as create analytical tools for data-driven decision-making.

- Integration Suite of Services: Supports integration scenarios through solutions like SAP Integration Suite, cloud connectors, SAP API Management, and SAP Data Intelligence.

- Artificial Intelligence (AI): Provides machine learning-based business solutions, tools for managing AI and machine learning models, and capabilities for creating, orchestrating, and managing chatbots. Powered by generative AI, it streamlines data management, automates processes, drives innovation, and enhances developer productivity. With access to large language models (LLMs), you can create tailored AI solutions while ensuring security and compliance through responsible AI practices.

By leveraging SAP BTP, organizations can accelerate digital transformation while SYSTEMA’s expertise ensures seamless integration and tailored support for unique manufacturing requirements.

Why partner with SYSTEMA?

SYSTEMA was one of the first companies to become a preferred SAP Manufacturing Service Partner when SAP began offering shop floor solutions and MES initiatives more than a decade ago. For 30 years, SYSTEMA has been providing manufacturers with a full range of IT-consulting and best practices to help maximize performance within their production environments.

SAP Manufacturing Consulting and Services

- Analysis and optimization of manufacturing processes

- Architecture and process consulting for manufacturing execution solutions

- Design and implementation of automation solutions

- Integration of standard SAP MES solutions

- Customized extensions for SAP MES solutions

- Equipment integration services (more than 10,000 equipment integrations worldwide)

- Execution of international projects from small to large scale

- Support for SAP MES implementations with 24/7 support operating 365 days a year