Stabilize highmix production with reservations, frozen horizons, and programmable constraints

SYSTEMA APS v2025.3 extends the predictive scheduling platform with new capabilities that make production plans more stable, more controllable, and easier to tune. This release focuses on reservation strategies, flexible constraint modeling, and benchmarking refinements, so line control engineers can shape schedules precisely to business and process needs.

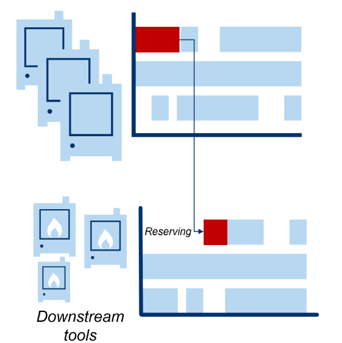

Machine Reservation & Reservation Strategies

Protect critical lots while keeping tools productive

v2025.3 introduces enhanced machine reservation to ensure that selected lots are processed as soon as they arrive at key tools:

- Reserve specific tools for an incoming lot or job, so it starts immediately after the current run finishes.

- Balance waiting for upstream WIP against tool utilization – particularly valuable for longrunning processes, hot lots, and “sendahead” wafers.

- Drive reservations via customizable logic implemented through the new Flexible Lot Filters (see below), so reservations follow your own rules for priority, product, or technology.

The result is more deterministic execution for critical work, with less manual intervention at bottleneck tools.

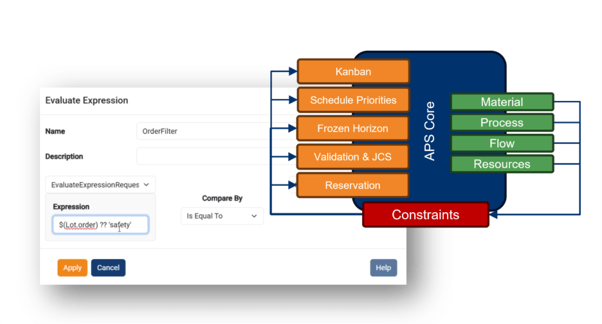

Flexible Lot Filters & Constraint Modelling

Programmable filters for Kanban, reservations, frozen horizons, and more

A new Flexible Lot Filter framework makes constraint modeling far more composable:

- Filter WIP for multiple use cases:

-

- Reservation strategies

-

- Unfreezing within a frozen horizon

-

- Kanbanbased WIP calculation

-

- Job-Centered scheduling

These filters are integrated into the APS runtime model (material, process, flow, resources, WIP), so the same building blocks can be reused across scheduling strategies instead of creating separate adhoc rules.

Frozen Horizon Scheduling

Reduce schedule nervousness without losing responsiveness

To keep schedules stable while still reacting to changing priorities, v2025.3 adds Frozen Horizon support:

- Define a time window (e.g., one hour) in which lot-to-Equipment assignments are “frozen.”

- Use “pinning” to preserve existing assignments and avoid unnecessary reshuffling of alreadyplanned work.

- Combine with Flexible Lot Filters to selectively unfreeze in special scenarios, such as newly released hot lots that must bypass the frozen plan.

This reduces schedule nervousness, improves operator trust, and makes production behavior more predictable for downstream stakeholders.

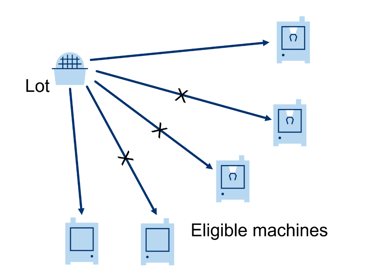

Job-Centered Scheduling & Configurable Process Validation

Intentionally limit eligible machines based on technical and business criteria

Job-Centered scheduling in v2025.3 introduces a configurable process validation step that controls which machines are eligible for a given lot or process step:

- Restrict processing to a curated subset of machines.

- Capture heterogeneity in your machine park, such as differences in:

-

- Yield performance

-

- Process times

-

- Setup effort

-

- Machine capabilities

-

- Energy demand and other secondary criteria

- Express these restrictions as modular validation rules, so engineering and quality requirements can be reflected directly in the scheduler.

This ensures that optimization never violates process standards, and that highvalue or sensitive products are scheduled only on approved tools.

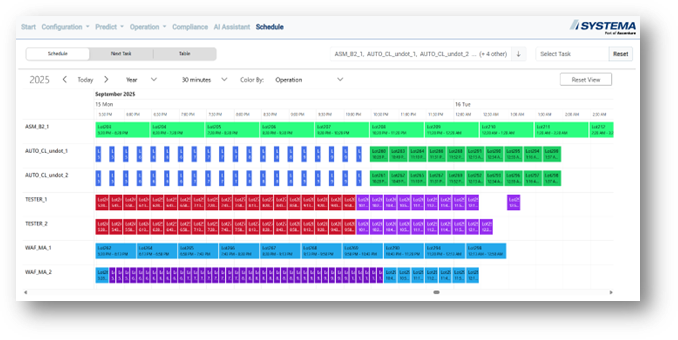

New Schedule UI

Real-Time schedule view with personalized filtering

The Schedule UI has been updated to provide a clearer, more configurable view of fab activity:

- Real-Time visualization of current and upcoming schedules.

- Significantly improved support for custom attributes, enabling richer context for lots and tools.

- Customizable filters so individual users can tailor perspectives to their role and focus areas.

- Bookmarks for table configurations, making it easy to switch between favorite views (e.g., bottleneck tools, hot lots, or specific product families).

These improvements reduce navigation effort and help engineers focus on the parts of the schedule that matter most.

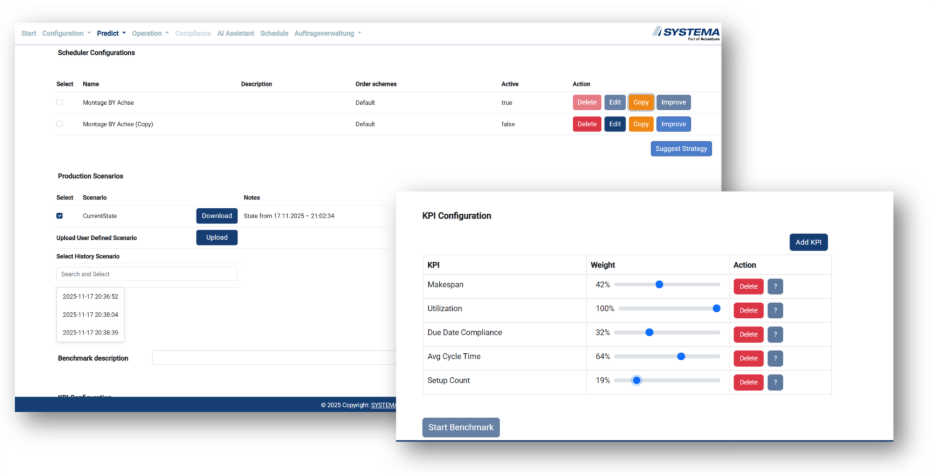

Benchmark Model Refinements

Configurable KPIs, global cost function, and replay

Building on the benchmarking introduced in earlier 2025 releases, v2025.3 refines the benchmark model to support more systematic comparison of scheduling strategies:

- Configurable KPI set – choose which metrics drive comparison (e.g., makespan, setup count, average cycle time).

- Global cost function – aggregate multiple KPIs into a single optimization score to quickly identify the best‐performing strategy.

- Reexecution of saved benchmark configurations – rerun previous scenarios when model assumptions, WIP, or equipment data change.

This turns benchmarking into a repeatable experiment framework rather than a on-off exercise.

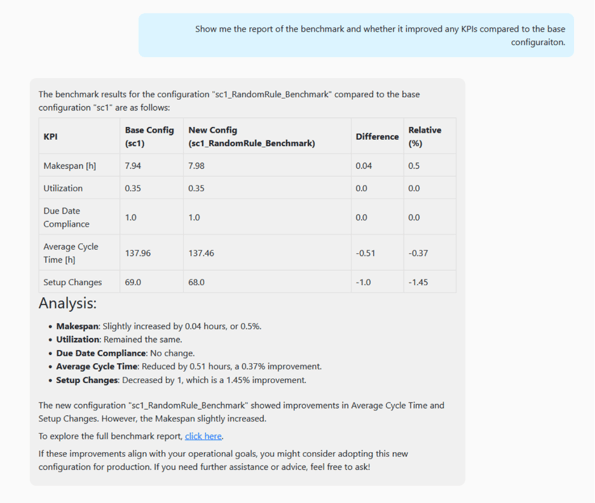

AI Assistant

AI-Enhanced Predictive Fab Analytics & Scheduler Assistant

v2025.3 introduces a new AI Assistant that brings explainability, transparency, and autonomous optimization to APS scheduling. The assistant helps engineers understand why scheduling decisions were made, explores what-if scenarios, and guides users toward the best scheduling models for their use cases.

With a customized LLM tailored to fab data and configuration, it can introspect current schedules, run benchmark experiments automatically, and suggest improvements for material flow and due-date compliance—making predictive scheduling more accessible and more powerful than ever.

Additional Enhancements in v2025.3

Beyond the headline features, this release adds a series of usability and modeling improvements:

- Lot Start Optimizer (Compare) – compare alternative lotstart strategies side-by-side.

- More finegranular BOM order scheduling – improved control for complex assembly and order structures.

- Modelfit improvements – better alignment between the digital scheduling model and real fab behavior.

- New menu structure – streamlined navigation across APS components.

- Configurable tile matrix – adapt dashboard tiles and layout to user preferences.

- Intralogistics support – extended capabilities to account for internal material movements in scheduling decisions.

Conclusion

SYSTEMA APS v2025.3 takes predictive scheduling to the next level by combining smarter reservation strategies, flexible lot filters, frozen horizons, and configurable process validation into one coherent control layer. These capabilities help manufacturers achieve more stable schedules, shorter and more predictable cycle times, and better use of critical tools—without sacrificing responsiveness to hot lots and disruptions. Ready to make your production plans both smarter and calmer? Schedule a demo today and see how SYSTEMA APS v2025.3 can transform your shopfloor performance.