Jim Connett, on January 08, 2019, 10:10 AM

E10 Unmasked – Part 3, Evacuations, Mindless Robots, and Missing Operators

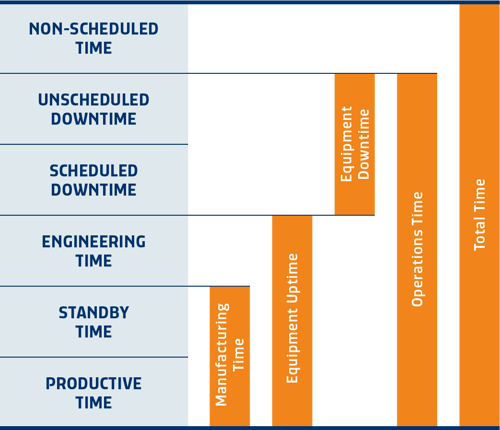

In the first installation of E10 Unmasked, we outlined E10 as a general concept. In Part 2, we looked at the first three (and most common) E10 tool states where a vast majority of time is collected: STANDBY TIME, PRODUCTIVE TIME, and ENGINEERING TIME. In this article, we are now going to explore the final three states: SCHEDULED DOWNTIME, UNSCHEDULED DOWNTIME, and…the ever-elusive and often-misunderstood NONSCHEDULED DOWNTIME. We will conclude with Part 4 and an examination of common questions received over the years specific to E10. In fact, if you have specific E10 questions, please feel free to email us.

Figure 1 – SEMI E10 defined “buckets” of time (Pomorski, n.d.)

SEMI E10 Scheduled Downtime

SCHEDULED DOWNTIME is self-defining. Most companies schedule maintenance events for equipment. These events could be as simple as gauge checks or as complex as full chamber deconstruction and reconstruction. In general, these preventive maintenance events will be iteratively scheduled (weekly, bi-weekly, annually) and will intentionally disable the tool in some way so that no production material will process through it during maintenance. The accumulated time when a tool is being serviced on a scheduled basis is collected under the SCHEDULED DOWNTIME state.

SEMI E10 Unscheduled Downtime

UNSCHEDULED DOWNTIME is equally self-defining. UNSCHEDULED DOWNTIME represents the amount of time in the reporting period where the tool was not processing material because of an unscheduled event that caused the tool to not operate in an expected or programmed way. Examples of unscheduled events may include a wafer breaking inside the tool due to heat stress, a downstream critical dimension measurement that indicates a specific tool is not operating within specifications, a controlling computer system on a tool whose hard-drive has decided to crash, or a robot that has lost its axis control and runs its transfer arm into the side of a chamber wall (yes, I’ve seen this happen, and it’s not pretty – bonus points if the robot runs into the side of a chamber wall with WIP on the arm). These are events we do not expect (or plan or anticipate), but they do happen. The time accumulated while the repairs are completed accrues in the category of UNSCHEDULED DOWNTIME.

SEMI E10 Non-Scheduled Downtime

What about this NONSCHEDULED DOWNTIME state? This final category of E10 is the most difficult to identify and measure. The complexities with NONSCHEDULED DOWNTIME usually compel companies to simply log NONSCHEDULED DOWNTIME as UNSCHEDULED DOWNTIME. We advise against this practice because it tends to skew the UNSCHEDULED DOWNTIME results and may lead to improper conclusions about maintenance processes and staffing.

So…what events qualify as NONSCHEDULED DOWNTIME? Here are a few examples:

I’ve worked for almost 20 years in the semiconductor industry and have participated in my share of real evacuations as well as evacuation drills. If a tool is not running productively when an evacuation occurs (or the tool is not in a SCHEDULED or UNSCHEDULED DOWNTIME state), an evacuation is considered NONSCHEDULED DOWNTIME.

Have you ever been in a manufacturing facility where laminar airflow ceases? Every hour of every day, the downward flow of air forces air particulates to the floor (or sub-floor). This is important for semiconductor manufacturing because one wayward particle floating in the air and landing on a wafer could render multiple die inoperative. When laminar airflow ceases, you feel lighter, fluffier and under less pressure. These are ALL bad things! A loss of laminar airflow is considered NONSCHEDULED DOWNTIME.

New tools being brought into the fab are installed, plumbed, connected to electricity and gasses, and exercised prior to being turned over to the engineering group. The time between installation and completion of installation is considered NONSCHEDULED DOWNTIME.

As a fab tech in the late ’90s, I’ve needed to work multiple areas of the fab during a given workday as my colleagues took a holiday or were sick. Because I cannot be in two places at once, my tools were often idle as a result of unavailable personnel. This is NONSCHEDULED DOWNTIME.

The easiest way to remember the difference between UNSCHEDULED DOWNTIME and NONSCHEDULED DOWNTIME is this:

UNSCHEDULED DOWNTIME occurs when an internal event occurs that adversely affects the performance/productivity of the tool whereas NONSCHEDULED DOWNTIME occurs when an external event occurs that adversely affects the performance/productivity of the tool.

Yes, this definition is not perfect, and many gray areas exist. Sometimes the event could fit under both categories, and the accuracy of these two states is largely dependent upon human intervention which adds to inconsistencies and discrepancies. As with all of the E10 states, it’s important to strive to apply the same conditions and criteria for each E10 state to every tool, even if the conditions and criteria don’t align perfectly with E10 standards. As strange as this may sound, being consistently wrong is better than being inconsistently right.

So, the next time the evacuation alarms sound, a robot yaws left instead of right, or half of the production operators call in sick, you’ll now know how to categorize this time using E10 standard definitions!

In our final installment of this series, we’d love to answer your questions involving your experiences with E10 and apply our experiences to your use-cases. Please feel free to email us at contact@systema.com and we’ll respond directly to you and also consider the question for inclusion in the final article (with your permission, of course!).

Be the first to comment.