- Jump to a section:

- Jump to a section:

Navigating the Automation Continuum

Manufacturers generally progress through five phases of automation as they advance their digital transformation journey. Movement through these phases isn’t strictly linear; factories may pilot new capabilities in a single tool family or production line to demonstrate value before scaling laterally across the enterprise. Each stage builds on the last, moving from manual, reactive practices to adaptive, model-driven operations.

Manual

In the manual stage, production relies heavily on paper travelers, spreadsheets, and tribal knowledge. Traceability is limited, firefighting is the norm, and key performance indicators (KPIs) are typically measured retrospectively, often on a weekly or monthly basis. Manufacturers at this stage operate reactively rather than proactively.

Digitized

As factories move into the digitized stage, electronic records and basic dashboards replace some manual processes. Limited MES use begins to emerge, but persistent silos remain between ERP, MES, and equipment. Improvements are often localized, resulting in pockets of efficiency but significant variability across the enterprise.

Integrated

At the integrated stage, systems and equipment are connected through a digital backbone that leverages message-oriented middleware and event-driven architecture. Stable identifiers and contextualized data create a single source of truth, enabling faster investigations and improved coordination across the factory. This marks the shift from fragmented processes to cohesive operations.

Automated

In the automated stage, rules-based orchestration becomes standard for tasks like dispatching, recipe selection, and interlocks. Automated holds and releases, exception workflows, and compliance features such as Electronic Records and Electronic Signatures (ERES) are implemented. Streaming data from SPC systems and synchronization with automated material handling systems (AMHS) further reduce manual intervention, driving consistency and efficiency.

Predictive/Adaptive

The predictive/adaptive stage represents the most advanced level of maturity. Here, models drive maintenance, scheduling, and process tuning, with humans remaining in the loop for governance. Closed-loop setpoint changes allow process parameters to be adjusted in real time based on sensor feedback, models, or algorithms. Continuous improvement becomes embedded at both the model and process levels, enabling truly adaptive manufacturing.

Transformation from analog to digital is a significant undertaking. However, careful planning yields benefits early in the process, with the quality and scope of optimization increasing progressively at each step toward higher levels of automation.

Due to the complexity and risk associated with digital transformation projects, it’s crucial to properly assess, scope, and follow strict project management principles (traditional or agile) while engaging a project manager with both breadth and depth of industry expertise.

Automation: A Human-Centric Effort

As human activities and knowledge are transformed into system performed actions and decisions, digital transformation is necessarily a human-centric effort. With all digital transformation initiatives, it is important to consider the effect they will have on the people involved. Remember to ask questions like:

How can the digital transformation improve operator safety and ergonomics?

In what ways can automation free people in the factory from the burden of remembering far more details and procedures than is reasonable?

How can digital transformation help improve productivity by managing and executing tedious or time-consuming tasks?

What professional development opportunities exist for affected workers as a result of our automation initiatives?

Engage people early to get their input, understand their concerns, and share with them how the automation initiatives will benefit them. Gather their requirements and feedback so that their suggestions can be incorporated into the planning throughout the digital transformation process. Additionally, identify opportunities for the creation of new roles within the organization which will allow workers to apply their skills and experience in new ways. By focusing on people first, any “disruption” caused by digital transformation will help those who are affected to see how the disruption will be a change for the better.

A Guide to Digital Transformation

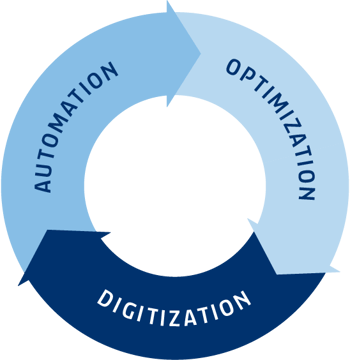

This guidance is based on SYSTEMA’s 30 years of experience in manufacturing automation. The ordering of the aspects of digital transformation presented in the guide is based on that experience as well as any dependencies that exist between automation initiatives (e.g. digital backbone is a prerequisite for equipment integration and automation). Conceptually, digital transformation can be viewed across three layers .

Organizational Efforts

Organizational efforts are largely addressed in the project management section. Organizational efforts include identification of business objectives, stakeholder alignment, agile methodologies, project planning, organization of project teams, development of change management strategies, and project execution.

Core Processes & Functionality

Determining the core processes and functionality required to support your digital transformation strategy will inform which system components will be needed and will also offer some insights regarding how to continue to progress along the automation continuum. Core processes and functionality may include WIP management and control, data collection, reporting and analytics, advanced manufacturing intelligence and high automation.

System Components

Identifying the system components which align with, and are required by, your digital transformation strategy will play a key role in determining an implementation and roll-out strategy. System components include MES, digital backbone, equipment integration and automation, Industrial Internet of Things (IIoT), recipe management, and automated material handling systems.

Digital Transformation: Key Benefits

- Improved productivity

- Staffing flexibility

- Reduced operator training time

- Reduced operator training expense

- Improved quality

- End-to-end manufacturing transparency

- Paperless manufacturing

- Manufacturing agility

- Improved efficiency

- Transparency

- Reduced costs

- Real-time data

- Future-ready manufacturing

The digital transformation process produces both short- and long-term benefits. Of course, there is a cost to undertaking a digital transformation and every factory is different. For this reason, appropriate analysis should be done to determine what makes sense for your individual situation.

SYSTEMA has experience with the digital transformation process as realized in several world-class manufacturing facilities.

One Fortune 100 technology manufacturer SYSTEMA worked with on their digital transformation reported the following benefits:

Benefits

A 50% increase in operations productivity as measured by WIP moves per operator per day

More flexible manufacturing staff requirements

Reduced cost and time for operator training

The company’s internal cost-benefit analysis shows the program saving the company $30 million USD per year

In short, they reported improved productivity, more flexibility, less training, and big savings. Your priorities might be different. Keep them in mind as you learn more about approaching digital transformation and think about how each step along the automation continuum can benefit the people and processes in your organization.