For SAP® Digital Manufacturing, SAP strongly recommends using Production Connector instead of SAP Plant Connectivity as your connectivity layer. SAP no longer supports SAP Plant Connectivity integration with SAP Digital Manufacturing.

SAP Plant Connectivity is SAP’s dedicated equipment integration solution for SAP Manufacturing Execution (SAP ME) and SAP Manufacturing Integration and Intelligence (SAP MII). Connecting production equipment with manufacturing IT systems enables highly automated production while providing the data necessary for material and process traceability and manufacturing analytics. Integrated equipment provides real-time data regarding production processes which enable data-driven optimizations around critical factory metrics and can help detect quality issues before they become scrap events.

What is SAP Plant Connectivity (PCo)?

SAP Plant Connectivity is the bridge between equipment and the MES. SAP Plant Connectivity enables the exchange of data between information technology and programmable logic controllers, Industrial Internet of Things (IIoT) devices, plant historian systems, and more in a manufacturing environment. Plant Connectivity queries data from source systems using a wide range of supported protocols. This data is sent by Plant Connectivity to the configured destination system such as SAP MII or SAP Manufacturing Execution, the SAP technology platform SAP HANA®, SAP Extended Warehouse Management, and SAP Digital Manufacturing.

Comparison: SAP Plant Connectivity vs. SAP Production Connector

SAP Plant Connectivity

SAP Digital Manufacturing, SAP ME, SAP MII

Different Operating systems

Configuration on premise

Web services available

Plant Connectivity supports the following standardized software interfaces:

- OPC UA client and flexible Web Service invocation (REST, SOAP, OData)

- OPC Unified Architecture (OPC UA)

- Web Socket Server, Web Server for Methods

- File interfaces

- Database

- TCP/IP

- OsiSoft

- Proficy historian

- Scheduled trigger

- IP21

- Modbus

- ODBC

- Asset framework

- Citect

- MQTT source and destination

- OLE DB

- Custom adaptor (SDK)

Production Connector

Only SAP Digital Manufacturing

Windows based

Configuration in the cloud (Control Center)

No web services

Production Connector agents support the following standardized software interfaces:

- OPC Data Access (OPC DA)

- OPC Historical Data Access (OPC HDA)

- OPC Unified Architecture (OPC UA)

- MQTT (You can connect the Production Connector to the SAP MQTT broker as an MQTT client.)

- IP21

- OsiSoft PI Asset Framework (PI AF)

Key Features of SAP Plant Connectivity

- Bi-Directional data exchange

- High-performance interoperability

- Machine protocol conversion and secure communication with SAP systems

- Configurable process sequences; orchestration of independent machine units

- OPC UA client and flexible Web Service invocation (REST, SOAP, OData)

- Web Socket Server, Web Server for Methods, OPC UA Server; MQTT source and destination

- Bundling and buffering of notifications; notification delivery retry; rule framework

- Remote configuration of Plant Connectivity from SAP MII

- Open for customer specific enhancements (proprietary protocols and complex processing logic)

Key Benefits of SAP Plant Connectivity

Benefits

Quick Configuration: Plant Connectivity can be configured quickly to connect source systems in production environments without additional development efforts within the existing manufacturing IT infrastructure

Single Platform: Plant Connectivity is the only platform needed for equipment integration to enable communication between equipment and various software systems on the shopfloor

Multi-Site Configuration: A Plant Connectivity system can be configured for one or more locations

Extensibility: Plant Connectivity can be extended via release compatible SDK

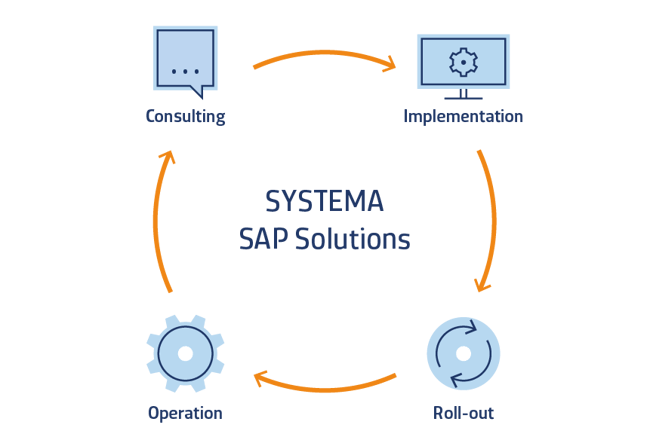

Why partner with SYSTEMA?

SYSTEMA was one of the first companies to become a preferred SAP Manufacturing Service Partner when SAP began offering shopfloor solutions and MES initiatives more than a decade ago. For more than 30 years, SYSTEMA has been providing manufacturers with a full range of IT-consulting and solutions to help maximize performance within their production environments.

At SYSTEMA, we understand the challenges that come along with integrating systems and equipment on the shopfloor. We have been doing this successfully while providing training, consulting and implementation of SAP Manufacturing solutions for manufacturers since 2009. A common theme in all our digital transformation projects is the alignment of all key representatives who will be impacted by systems, technology, and process changes by enlisting their feedback, understanding their questions and concerns, and developing solutions with the end-users in mind. Further, we provide the support and services necessary to guide the change process from start to finish and empower users to effectively leverage the system without ongoing external support.

SAP Manufacturing Consulting and Services

- Analysis and optimization of manufacturing processes

- Architecture and process consulting for manufacturing execution solutions

- Design and implementation of automation solutions

- End-to-end implementation of SAP MES solutions

- Customized extensions for SAP MES solutions

- Equipment integration services (more than 10,000 equipment integrations worldwide)

- Execution of international projects from small to large scale

- 24/7 Application Management Services for SAP Manufacturing solutions