Jim Anderson, on May 02, 2019, 07:24 PM

Dispatching to Reduced Capacity Equipment

In a typical semiconductor fab environment, there may be several tools that can process lots at a given step in the workflow. But, life happens, and when a particular lot arrives at a work area, the reality may be that not all of them are truly able to process that lot at that moment. Perhaps a tool has a chamber that is down for repair and it can execute some recipes, but not others. Or there might be some output characteristic of a tool which has been measured and found to be out of range for certain products (as might happen with equipment whose performance changes over time due to some contamination buildup). An automated dispatching solution can seamlessly handle this to maximize production capacity.

Lot Prioritization Based on Equipment Capability

Manufacturing lines are very dynamic environments with equipment status and capabilities frequently changing, and products arriving and departing each work area. With the right information about tool capabilities and product requirements, an automated dispatching system can help equipment operators determine which lots to run on which tool at any given moment. A dispatcher can do this simply by giving higher priority to lots in dispatch lists for equipment that meets all processing requirements and disallowing them from selection on dispatch lists for equipment that does not.

Example: Reduced Capability Equipment

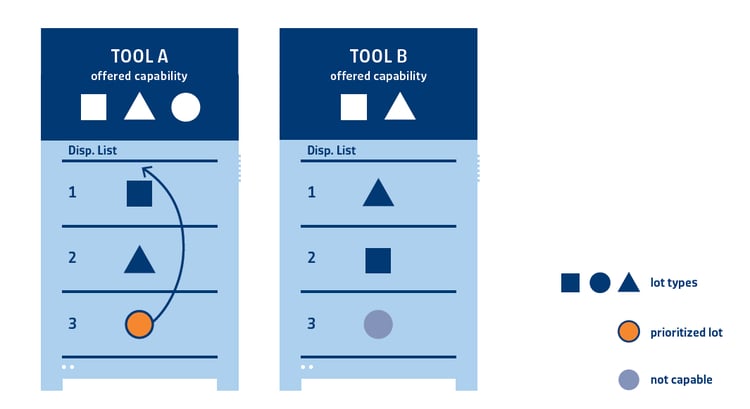

Consider a simple example as shown in Figure 1. Here, there are just two pieces of equipment, called “Tool A” and “Tool B”. The material to be processed includes three different product types represented by the square, circle and triangle. Under normal circumstances, both Tool A and Tool B can run material of all three product types.

But say, for some reason, Tool B can’t currently run “circle” products and is only offering the capability to run “square” and “triangle” material. When this happens, Tool A becomes the only piece of equipment that is capable of processing “circle” material.

Figure 1: Lot Prioritization for Reduced Capability Dispatching

Reduced Capability Equipment: Dispatching Solution

In the example above, an automated dispatching system should do two things. First, assuming there are no other priority rules that take precedence, it should prioritize “circle” material above all other material on Tool A. Second, on Tool B, the “circle” material should still be shown in its dispatch list, but the dispatcher should mark it as “not available to be processed” because Tool B is not currently offering that capability.

This example can easily be extended to more than two tools, with the general principle being that the smaller the percentage of tools that are capable to run products of a certain type, the higher priority the dispatcher will give that material on the tools that can process them. Alternatively, if there are no tools that are capable to process a particular product type, the dispatcher can alert fab management of a blocking condition.

For more information on how to approach digital transformation strategies, such as automated event-driven dispatching, check out SYSTEMA’s guide to digital transformation.

Be the first to comment.