Axel Wogawa, on June 22, 2020, 11:26 AM

Industry 4.0: Cloud-Based Equipment Health Monitoring

The Industrial Internet of Things (IIoT) and cloud computing are key enablers of modern Industry 4.0 automation solutions. For example, by using artificial intelligence, we help customers build smart manufacturing solutions that allow the prediction and prevention of equipment failures. However, there’s often a lack of clarity regarding these technologies which may inhibit adopting them. We set out to address the following questions around these technologies:

- What steps are involved in integrating internet technology (IIoT, cloud) with existing automation technology (AT) equipment?

- How can cloud services be used to build a robust, modular software system for processing IIoT data streams?

We conducted considerable research in an attempt to answer these questions and shed some light on this large solution space. We focused on a Condition Monitoring (CM) use case to

- track the current health status of a system, e.g. an industrial production machine, in real-time and to

- initiate actions to avoid damage or production faults.

Below, we have shared our findings regarding the software architecture and IT-AT integration aspects. We begin by looking at the architectural patterns that were followed to design our system. Then, we present our proof-of-concept for a CM system design based on the Microsoft Azure IIoT cloud service stack. We conclude with a summary of the insights we gained throughout this project.

Key Benefits of Condition Monitoring

|

WIP MANAGEMENTAvoid material accumulation by |

|

OEE MONITORINGUnlock unused capacity using a holistic 4M |

|

WASTE REDUCTIONMinimize scrap by quickly |

|

REDUCE THE NEED FOR SERVICINGEnable tool wear dependent service |

Reference Architectures for Cloud Computing, IIoT and Condition Monitoring

The first part of our research was to analyze existing software architecture guidelines for cloud computing, IIoT and CM to avoid reinventing the wheel. Despite of the huge number of available guidelines calling themselves reference architectures, we found it sufficient to focus on two of them: one that covers the cloud computing and IIoT aspects, and the other specialized in industrial CM. Our goal was to consider modern cloud architecture patterns as well as industrial AT aspects.

We chose Microsoft’s cloud platform Azure – one of the biggest players on the cloud market – as the technology provider for our application. Microsoft published an extensive whitepaper, called the Microsoft Azure IoT Reference Architecture, explaining their take on how to build an IoT application using Azure services like IoT Hub, IoT Edge Runtime and Stream Analytics. We investigated this guideline and found it to be a great guide for selecting and combining the main building blocks of Azure’s IoT world. The document provides comprehensive high-level information about IIoT cloud applications, even beyond the Azure service offer scope. Together with the extensive online documentation of the Azure services, these resources provide valuable support for engineers of IIoT cloud applications. For that reason, we chose to base our CM application on this guideline.

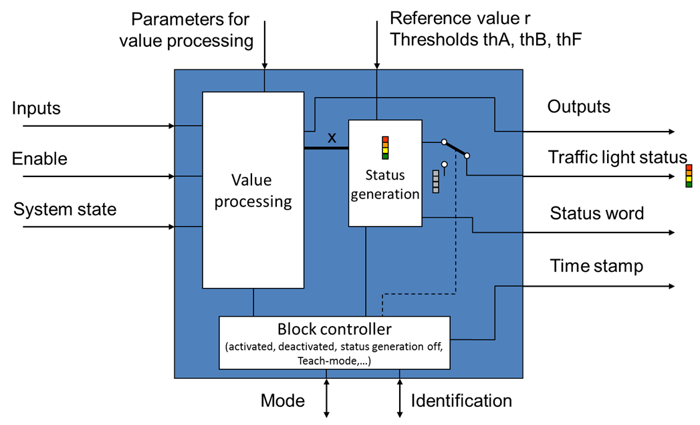

The second reference architecture we focused on is the CM specification VDMA 24582:2014-04: ”Fieldbus neutral reference architecture for Condition Monitoring in production automation”. It deals with the topic CM from an industrial automation point of view and has the goal to standardize the general structure and interface of industrial CM applications. The core element of this architecture, shown in Figure 1, is the uniform function block that structures and encapsulates CM functionality in a well-defined way. The uniform function block serves two purposes. First, it defines the general building blocks of typical industrial CM logic, second, it helps to to build a consistent interface to existing industrial automation networks.

Figure 1: The VDMA 24582 uniform function block – the standard structure, in- and outputs of CM functionality.

Bridging Automation Technology with Information Technology: Our System Design

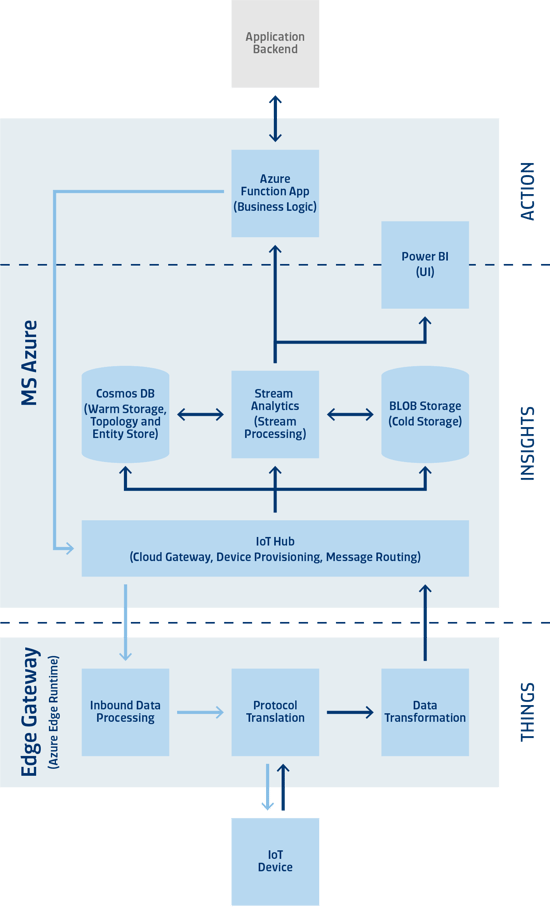

Based on the references discussed above, we designed a generic architecture for an IIoT- and cloud-based CM system. In Figure 2 you can see how it’s composed of several Azure IIoT services and Azure reference architecture components. We found that, for the most part, the Azure services contain remarkably rich and mature functionality.

Figure 2: The building blocks of our CM system design. Each “IoT Device” streams data via an “Edge Gateway” to the cloud, where the “Stream Processing” logic determines the system health status and generates real-time status change events.

The Edge Computing Part

What is edge computing?

- extend cloud computing by a local compute node (“edge gateway”)

- perform local processing (data transformation, aggregation, ML-based smart edge processing, …)

- reduce upstream data

- low-latency processing/storage

Azure IoT Edge Runtime is the solution we selected for our concept to simplify building edge-computing logic and connecting local infrastructure to the cloud. With Runtime handling most communication and module management details, we were able to focus on building logic for protocol translation and data preprocessing on top of it.

The Cloud Part: Stream Processing and Business Logic Services

Cloud SaaS offerings can help reduce engineering effort and cost.

Azure IoT Hub and Azure Stream Analytics are further examples of cloud services to enable modern IIoT solutions. They provide message routing, device management and sophisticated data stream processing. Software as a Service (SaaS) offerings like these are one major strength of the cloud in general – the built-in functionality dramatically reduces engineering effort. Instead of having to design and build all internals of such features (communication, crypto, database, runtime handling etc.), one can just parameterize and create service instances as needed and start implementing business logic immediately. Even if not everything about these services is perfectly mature yet, our concept and the design process dramatically benefited from them.

Integrating Factory Equipment with the Cloud

The Function App API and the data processing logic running in Stream Analytics are inspired by VDMA 24582. It was interesting to see how two guidelines proposed by such different institutions as Microsoft and VDMA could be implemented in a unified solution without fundamental contradictions. This is possible, because they target different areas – Microsoft addresses the architecture of a stream processing pipeline in a cloud-IIoT application while VDMA leverages established principles of industrial CM logic and aspects of interoperability. Both concepts are equally important when using the cloud in an industrial context.

The cloud solution will most likely have to interact with an existing AT infrastructure. For example, it may be responsible for sending events to an enterprise resource planning (ERP) system or reading sensor values from a programmable logic controller (PLC). To make the cloud application interact as smoothly as possible with the AT domain, it must adhere to the communication principles of the AT domain. At the same time, the application has to be designed such that it becomes robust, maintainable and can leverage the advantages of the cloud.

Condition Monitoring IIoT Solution: Proof-of-Concept

To validate our ideas, we implemented a prototype for a simple use case: monitoring a PC fan’s speed and vibration. IIoT sensors measure these parameters, the data stream is being processed on the edge and in the cloud. Local LEDs are displaying the system health status. As the fan speed falls below a certain threshold or the vibration gets too strong, the system is automatically being switched off. This example shows how an industrial asset, such as a CNC drilling machine, can be monitored in real-time with our cloud-based system while providing automatic emergency measures to prevent damage.

Click the video below to see the prototype in action.

Industrial Cloud Computing Insights

We are able to connect industrial equipment and the cloud by considering requirements of both domains.

To converge on a system that meets industrial automation, IIoT and cloud requirements, we combined best practice patterns from Microsoft’s IoT Reference Architecture with core automation principles from the VDMA 24582. Timing and security requirements of industrial applications and communication boundaries between AT and IT equipment often make merging these two domains a daunting task. By combining aspects of both areas, we got closer to bridging this gap. The VDMA specification emphasizes interoperability aspects and structures the CM functionality from an industrial point of view. On the other hand, the Azure reference architecture enables IIoT through a modern, modular and scalable system architecture. Using Azure’s IIoT services, which come with a lot of useful built-in functionality, it is possible to dramatically reduce engineering and operation effort of such an application. All in all, this is a promising approach leveraging the flexibility and power of the IIoT and the cloud.

There’s much more to CM, IIoT and the cloud than what can be covered here. What advantages does the cloud offer over conventional on-premises computing? What are the drawbacks? Further topics of interest are data analytics, machine learning, device management, and data security. We’re continuously deepening our knowledge in these areas. If you’re also curious about possibilities with the cloud, IIoT, or industrial automation solutions be sure to follow our blog or feel free to contact us – we’re always happy to get in touch with you!

Be the first to comment.