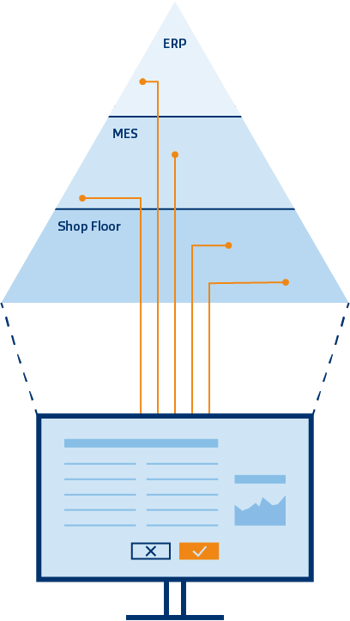

As the complexity of products and manufacturing processes increases, so does the opportunity for human error in material processing and data collection. Integration and automation of the equipment used in the execution of manufacturing processes offers a solution to prevent those errors from occurring. Equipment integration and automation provides a means of accurate and timely data collection, process controls, and optimization efforts.

Achieving high levels of automation depends on robust, standardized equipment integration. Tools, subsystems, and automation frameworks must exchange data in real time, with context and consistency, to enable traceability, optimize performance, and support predictive decision-making. Without consistent connectivity and parameter control, manufacturers face silos, delays, quality risks, and limited visibility—preventing them from scaling toward adaptive, high-automation fabs.

Importantly, equipment integration isn’t only about connecting machines. It’s about creating a cohesive operational ecosystem where each tool, chamber, and process step becomes a data-rich, orchestrated contributor to overall factory performance.

Benefits

Equipment integration and automation benefits equipment operators, production managers, production engineers, and the overall enterprise. Some areas where benefits can be seen:

Benefits

Accurate and timely data collection for data-driven decision making

Enhanced quantity and fidelity of collected data provide a foundation for advanced analytics and predictive AI

Reduction of scrap and increase in yield by automatically controlling and adjusting the process at the equipment

Improved equipment utilization by removing delays caused by unavailable operators

Visibility into the state of production, enabling staff to understand quickly where and why the production landscape is experiencing issues

Complete traceability and compliance through electronic records and contextualized data

Core Concepts

Manufacturers leverage a wide range of process automation capabilities and commonly have at least some level of automation along with other manual efforts. The level of manufacturing process automation can range from basic to high automation. Achieving higher levels manufacturing automation capabilities depends largely on:

- Current communication capabilities of the existing components

- Effort required to develop the capabilities that don’t currently exist

- Budget for such initiatives

Basic Equipment Integration

Basic equipment integration describes a level of automation where the data acquired through integrated equipment is one-directional. Data is simply retrieved from the equipment by another system that facilitates the execution of production processes, perhaps a manufacturing execution system (MES). This enables automated data collection and cycle counts, provides equipment status information to higher-level systems, and increases traceability .

Paperless Manufacturing

Paperless manufacturing refers to a state of digitization that has successfully eliminated any and all paper from the production floor. In a paperless manufacturing environment, everything is digitized. There are no paper travelers, written or oral transcripts, paper work instructions, notes, etc.

While not a prerequisite for equipment automation, paperless manufacturing shares common foundations, such as:

- All processes, work plans, operations and facilities must be modeled in the manufacturing execution system (MES)

- All material must be modeled and tracked in the MES

- Business logic for decision making on losses, rework, sampling, dispatch, capability models, etc. be stored and executable in the MES

These requirements are fundamental to both paperless manufacturing and equipment automation.

Equipment Automation

Equipment automation is characterized by the ability for an application or system within the production environment to control the actions of the manufacturing equipment. Typical functions include:

- Validation of all prerequisites for a production process (e.g., equipment readiness, material availability, recipe approval)

- Automated recipe selection and parameter download

- Automatic process start once prerequisites are met

- Process stop if errors or exceptions occur

Automated Production Processes

A production process is considered to be automated when there is no human interaction with the production process, other than for fault and failure handling. Equipment automation facilitates automated production processes.

Highly Automated Manufacturing Environments

A manufacturing environment is considered highly automated when most production processes are automated and workflows are system-driven, with operators in supervisory roles. At this stage, manufacturers often pursue or optimize:

- Automatic identification of carriers and/or material

- Automated material handling and transport

- Coordination of automated material handling with still necessary manual interactions

- Automation of failure, fault, and exception handling

- Automation of equipment qualifications

- Advanced manufacturing analytics powered by chamber-level data, SPC/APC feedback, and predictive models

Considerations

Before approaching equipment integration and automation initiatives, it’s important to clearly identify:

- Main goals (e.g., error prevention vs throughput optimization)

- Existing processes that have to be automated or changed

- Opportunities for process standardization

- Availability of stakeholders (e.g., production, industrial engineering, equipment engineering, IT/OT, etc.) to guide the solution

- Budget and resources available

Done correctly, equipment integration and automation can be an iterative process beginning with the most important things first while simultaneously laying the foundation for more advanced functions to be implemented in later phases.

Goals

Integrating manufacturing equipment with other IT systems and enabling those systems to control manufacturing equipment accomplishes the following:

- Prevents errors and misprocessing

- Enables accurate and timely data collection

- Improves product quality

- Establishes standardized workflows with customization by equipment, product, or process scenario

Prevent Errors & Misprocessing

Automation is critical for eliminating error-prone scenarios, such as:

Recipe Selection

Some manufacturing equipment require the specification of settings and parameters to ensure the equipment functions such that it will correctly process material at a given step in the production flow. Different products and different steps in the production flow may require modifications to settings and parameters on the equipment. These settings and parameters are generally referred to as a “recipe” and a given piece of equipment may support many different recipes. This allows flexibility for a single piece of equipment to process a wide variety of products.

This flexibility comes with the risk that, if the wrong recipe is selected, the material being processed could be rendered unusable. To reduce the risk, automation software can be used to select the correct recipe and to instruct the equipment which recipe settings and parameters should be used. Accurate recipe selection eliminates a significant source of misprocessing in many manufacturing settings.

Equipment & Lot Compatibility

At each step in the process flow, material must be processed on the correct equipment. Automation ensures this accuracy by checking with the tracking system, often an MES, to confirm that the equipment is valid for the lot, product type, and step in the flow.

In a manufacturing line with multiple instances of the same type of equipment, there may still be other differences between each piece of equipment that can affect whether the lot should be processed there. In this case, automation communicates with the equipment to verify that the equipment currently offers the process capabilities that the lot requires at the current step in its process flow. Automating these verification processes ensure production flows efficiently and correctly.

Lot State, Equipment State & Condition

Not only do lots and equipment need to be compatible, they both need to be in the correct state before processing can continue. There can be many conditions that need to be true for the lot and many other conditions that need to be true for the equipment before a lot can be processed on it. These conditions will vary depending on a manufacturer’s business rules. Some typical examples that automation can check for include verifying that the lot is not on hold for review, or that the equipment is not down for preventive maintenance. Relying on automation to gather information from multiple systems to verify multiple conditions significantly reduces the possibility of errors in processing.

Enable Manufacturing Analytics with Automated Data Collection

Paper travelers have largely been replaced by manufacturing execution systems (MES) for process controls and for the capture of product and processing data such as product, lot number, quality data, and timestamps for track-in and track-out operations. While an MES tremendously improves the timeliness and accuracy of collected data, equipment integration and automation further enhance the automated collection and sharing of information between manufacturing IT systems. The many points of data that can be collected efficiently and accurately with automation provide the basis for advanced manufacturing intelligence, predictive AI, and advanced planning and scheduling capabilities.

Improve Product Quality

Integrating manufacturing equipment with other manufacturing IT systems like statistical process control (SPC) systems, which handle the collection and processing of metrology data necessary for controlling product quality, provides accessibility and visibility into quality data which can be used by the automation system to optimize production processes in order to improve product quality.

Advanced process control (APC) systems make use of sensors and other devices to monitor the health of shopfloor equipment and provide verifications, such as to verify temperatures within an oven chamber. APC systems allow for process optimization and provide information necessary for determining necessary equipment maintenance. Integration and automation of equipment with APC systems allow for real-time automated control of equipment to execute process adjustments based on outcome of product at a particular stage in order to ensure and improve product quality.

Functions

Equipment integration and automation involves the connection of systems and orchestration of automation scenarios:

Connection of Systems

One major benefit of automation is realized by its ability to connect manufacturing equipment to other manufacturing IT systems within the manufacturing environment. Automation then serves as a layer of abstraction between the particular equipment interface and the rest of the factory data systems. The result is a tremendously simplified interaction for the end-user in that they no longer have to interact directly with each system individually. They simply interact with the automation interface, which then handles the interactions with all underlying systems.

Manufacturing equipment types vary greatly in the ways in which they present connection interfaces to automation, ranging from industry standard formats to no interface at all. Regardless of the type of connection interface offered by the manufacturing equipment, automation can act as a bridge between the equipment and other manufacturing IT systems. The types of interfaces offered by manufacturing are numerous and can include:

- SECS-GEM

- OPC UA

- MQTT

- Modbus

- MTConnect

- Web services

- File systems

- Proprietary protocols

- IIoT gateways

- And others

Orchestration of Scenarios

As material moves through a manufacturing line, there are usually some common activities that take place, regardless of the material’s particular product or processing step. These activities are required by the business rules of the organization, and serve purposes like consistent tracking, validation of material ID, confirmation of equipment readiness, and so on. These activities can be organized into common “scenarios” which can be handled by automation software at each processing step. By identifying and standardizing common scenarios, the automation can present a common and familiar processing sequence to a manufacturing operator at each step in the material flow and that processing sequence can then be applied to provide automation for many different process scenarios. A simplified standard scenario might look like this:

- Fetch material to be processed

- Identify the material at the equipment

- Verify material is at the appropriate manufacturing step and equipment

- Verify the equipment is ready to process the material

- Select/download recipe for material

- Track in the material (in MES)

- Process the material

- Collect data for use by MES and other systems

- Track out the material (in MES) and move it to the next step

If a particular process step or product requires additional or exceptional activities, the standard automation scenario can easily be modified or extended to accommodate them. The advantages of using automation to orchestrate common processing scenarios includes:

- Equipment operators can be more easily trained on the common scenario and can easily learn a few exceptions, rather than having to learn different scenarios for each and every product and process.

- Consistent application of business rules ensures proper product tracking and verification, and validation of equipment readiness, thereby reducing the chance of untraceable or incorrectly processed material.

SYSTEMA’s Perspective

At SYSTEMA, we understand the risks and challenges that come along with implementing automation solutions on the shopfloor. For more than 30 years, we have integrated heterogeneous equipment fleets across complex manufacturing environments, using standards-first approaches, parameter governance, and real-time orchestration. By enabling robust equipment integration, SYSTEMA helps manufacturers reduce risk, achieve traceability, and lay the foundation for predictive-ready operations and adaptive automation—cornerstones of digital transformation.