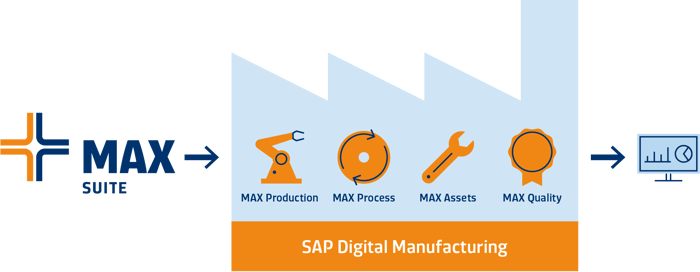

What is SYSTEMA’s SAP Manufacturing Accelerator Suite (MAX Suite)

SYSTEMA’s SAP Manufacturing Accelerator Suite (MAX Suite) is a highly configurable, customizable, and rapidly deployable framework that offers modules which can be implemented individually or combined to provide MES-like services for process industries. By integrating production and business data, MAX Suite contextualizes information collected on the shopfloor to provide visibility into manufacturing operations and allow management to quickly and confidently make data-driven decisions.

Built on SAP Manufacturing Integration & Intelligence (MII), MAX Suite comes preconfigured and offers further customization options to address the specific needs of your production environment. MAX Suite’s native integration with SAP ERP and SAP Plant Connectivity (PCo) ensures ongoing compatibility with SAP’s Digital Manufacturing solutions. SYSTEMA’s MAX Suite has been operating successfully in major production facilities for over a decade and is deployed in more than 50 plants worldwide.

Benefits

Centuries of combined manufacturing, automation, and software development expertise built-in

Rapid implementation and deployment to one or more sites

Anytime, anywhere visibility into manufacturing operations with mobile device accessibility

Proven solution based on trusted SAP technology

Key Features

- Preconfigured solution designed for process industries

- Scalable and capable of quick deployment across multiple sites

- Process, Production, Assets, and Quality functional modules can be implemented individually or combined to provide MES-like services

- Configurable workstations

- Factory Database (FDB) allows a factory to work independent of SAP ERP in the event of an outage, with automatic synchronization when connection is restored

- Integration-ready for SAP Digital Manufacturing for insights (DMi)

- Web application provides anytime/anywhere accessibility via internet-connected devices

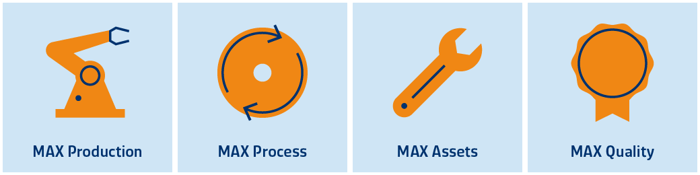

Modules

MAX Suite offers the following modules which can be implemented individually or combined to provide MES-like services for process industries:

Production Module

MAX Suite’s Production module offers a key advantage in monitoring, managing, and optimizing production activities due to its ERP system integration. Production planning activities conducted within the ERP are integrated with actual results produced on the shopfloor. This provides context and allows for comparison of planned versus actual results to help determine true material consumption and replacement needs, maximize resource allocations, and optimize production activities.

Production Module | Key Features

- Trigger ERP activities to adjust staffing requirements, adjust material orders based on consumption, and adjust production plans by accounting for resource availability

- Shift Control Logbook provides shift supervisors with an overview of operators’ activities to allow for additional production monitoring and control including: production order fulfillment planned vs actual; equipment status; production KPIs for shift events, inventory and materials, and more

- Production schedule is presented on operator workstation showing orders for specified shift along with details like status, BOM, comments, and activities to be performed in sequential order

- All activities for a workstation are presented on the same screen, eliminating the need for operators to switch screens to perform different activities

- Information is provided for inspection by the equipment operator regarding quality data, defects, and characteristics of raw materials used

- Factory database approach enables independence from ERP to provide peace of mind in the event of ERP system outage that orders will continue to execute and be accessible

- Automatic upload of results of production outcomes and material consumption to ERP

- KPI monitoring: Production plan vs actual results

Process Module

MAX Suite’s Process module provides easy-to-use analytics capabilities which are a robust and powerful tool for evaluating manufacturing processes and identifying where process optimizations are needed. Utilities within this module are highly flexible and customizable by the user.

Process Module | Key Features

- Data collection and process variables analysis

- Real-time process monitoring for individual production orders

- Visualization and analysis of process variables

- Workflow alarms alert key personnel of process variable and task deviations

- Dynamic reporting and ad-hoc report creation capabilities

- SPC/SQC Module alarms

Asset Module

MAX Suite’s Asset module drives optimal resource utilization. This module provides real-time OEE monitoring to visualize and make data-driven decisions regarding quality, productivity, and equipment utilization optimizations.

Asset Module | Key Features

- Real-time OEE monitoring for individual production orders

- Downtime controls justified by appropriate catalogues/standard reason codes

- Evolution chart and order execution forecast based on capacity and performance history

- Provides the operator with a tool capable of detecting deviations to aid in real-time optimization of production

- Equipment maintenance activities can be triggered manually or automatically and sent to SAP PM module

Quality Module

MAX Suite’s Quality module captures, calculates, and manages quality data to affirm that finished products meet customer requirements and ensure that production records include the necessary documentation to demonstrate compliance with established regulatory and other standards.

MAX Suite Quality | Key Features

- QMS Integration

- Material Dispositions (determine and record the disposition of material directly from a workstation)

- Inspection Lot Handling function updates QMS with results of quality inspections directly from the workstation

- Sample Management (prerequisite for LIMS integration) system logs sample data along with context information; log is created regarding sample sent to lab for analysis; lab analysis/outcome is logged in system with context information to determine disposition; disposition status is logged in system)

- LIMS Integration to collect, store, and manage results and processes necessary to prepare samples for sending to the lab

Recommended Technology

SYSTEMA recommends the following technology landscape:

- SAP S/4HANA or SAP R/3-ECC 6.0 with EHP 6.0

- SAP Modules PP or PP/PI, QM, PM and QM with standard implementation

- SAP MII 15.3 or later

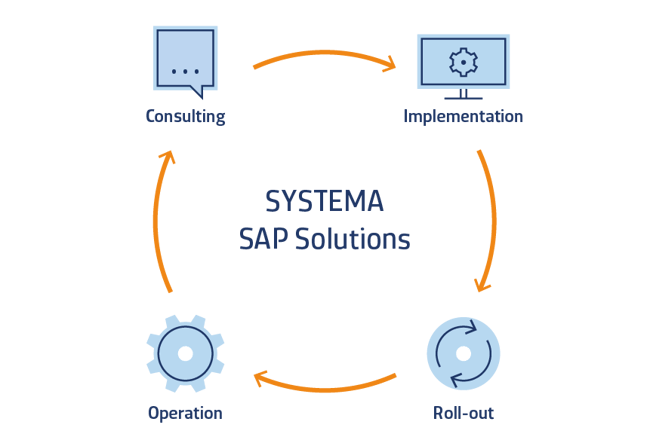

Why partner with SYSTEMA?

At SYSTEMA, we understand the challenges that come along with implementing new technologies on the shopfloor. We have been providing training, consulting and successful implementations of SAP Manufacturing solutions since 2009. A common theme in all of our digital transformation projects is to align all key representatives who will be impacted by systems, technology, and process changes by enlisting their feedback, addressing questions and concerns, and developing solutions with the end-users in mind. Further, we provide the support and services necessary to guide the change process from start to finish and empower users to effectively leverage the system without ongoing external support by providing the necessary training.

SYSTEMA was one of the first companies to become a preferred SAP Manufacturing Service Partner when SAP began offering shopfloor solutions and MES initiatives more than a decade ago. For 30 years, SYSTEMA has been providing manufacturers with a full range of IT-consulting and best practices to help maximize performance within their production environments.

SAP Manufacturing Consulting and Services

- Analysis and optimization of manufacturing processes

- Architecture and process consulting for manufacturing execution solutions

- Design and implementation of automation solutions

- Integration of standard SAP MES solutions

- Customized extensions for SAP MES solutions

- Equipment integration services (more than 10,000 equipment integrations worldwide)

- Execution of international projects from small to large scale

- Support for SAP MES implementations with 24/7 support operating 365 days a year